- Description

- Inquiry

Vacuum plasma surface trentment machine,Drum type 360-degree plasma cleaner,Miniature plasma generator

Product characteristics

1. Change the surface properties of materials, improve adhesion

2 The equipment adopts PLC touch screen control, simple operation and easy maintenance

3. Unique electrode structure, ensure plasma uniformity

4. Good safety, multifunctional safety protection

5. Improve production quality, environmental protection and energy saving

Vacuum plasma surface trentment machine,Drum type 360-degree plasma cleaner,Miniature plasma generator

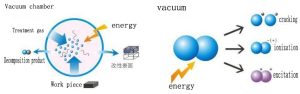

Plasma cleaning principle

plasma cleaning technology uses the characteristics of low temperature plasma to contact and react with the surface of the material, so that the surface of the material being treated can be cleaned chemically and physically, improve the surface moistness, implant new chemical functional groups and surface etching.

Vacuum plasma surface trentment machine,Drum type 360-degree plasma cleaner,Miniature plasma generator

Product parameter

Application industry

Photoelectric and electronic industry applications

1. All kinds of glass surface cleaning, improve the hydrophilicity of glass surface, optimize the process of glass coating printing, bonding and spraying;

2. Flexible and non-flexible printed circuit board contact cleaning, LED fluorescent lamp “contact cleaning and improve the surface glue fastness; 3. Electronic components, PCB cleaning, IC and other surface cleaning, activation enhancement binding, etc. 4.LCD terminal before bonding plasma cleaning;

Automotive industry application

1. Car EPDM seal strip, flocking and coating pretreatment instead of the use of bottom coating

2. Car lamp base, groove, brake pad, bumper bonding, plasma pretreatment before spraying;

4. Welding of battery pole piece for new energy automobile, activation of surface before coating, cleaning, etc.

Plastics industry application

1.PP, PVC, PET, PC, PE, PTFE and other types of plastic materials spraying, printing, electroplating, bonding and flocking pretreatment;

2. All kinds of plastic, silicone, rubber, metal and other materials spraying, printing, plating bonding before surface modification, removal of surface pollutants;

3. Pretreatment before printing and painting of mobile phones, computers, toys and other plastic shells to improve surface adhesion;

4. Plastic cosmetic bottle preprocessing before printing, improve surface adhesion can prevent word falling off and improve product quality;

Packaging industry application

1. Professional improvement of coated paper, glazing paper, polishing, gold and silver card, aluminum plated paper, UV, OPP, PP, PET and other color boxes, color box surface paste box fastness;

2. Plasma pretreatment before welding of milk powder cans and beverage cans;

Printing and coding industry applications

1. Plasma pretreatment before pad printing, screen printing and jet coding on the surface of plastic, metal, glass and other composite materials to improve the adhesion of material surface to ink;

2.PE, PTFE, silicone rubber wire and cable coding pre-processing

3.PVC, PET, ABS smart card coding pre-processing

Appliance industry application

1. Plasma activation before surface coating, spraying and bonding of daily necessities and household appliances can improve surface adhesion and bonding force.

2. Pre-printing processing, which can make the printing more firm and not fall off:

GD-30 series plasma cleaner is located in the industrial production of low temperature plasma treatment equipment, widely used in electronics, solar energy, automotive, textile, packaging printing, biomedical and general industries, its characteristics are high processing efficiency, good repeatability, good stability, easy operation, variety of process parameters, diversified tasks. It is suitable for cleaning, activation, improving adhesion, adhesion and etching and other processes, and can be customized according to different needs of customers with professional, efficient and stable solutions, which perfectly fit the medium and large production needs of enterprises and companies.

GD-30 series plasma cleaner is located in the industrial production of low temperature plasma treatment equipment, widely used in electronics, solar energy, automotive, textile, packaging printing, biomedical and general industries, its characteristics are high processing efficiency, good repeatability, good stability, easy operation, variety of process parameters, diversified tasks. It is suitable for cleaning, activation, improving adhesion, adhesion and etching and other processes, and can be customized according to different needs of customers with professional, efficient and stable solutions, which perfectly fit the medium and large production needs of enterprises and companies.