- Description

- Inquiry

plasma surface treatment machine,Product adhesion improved,Surface treatment before bonding

Activated surface

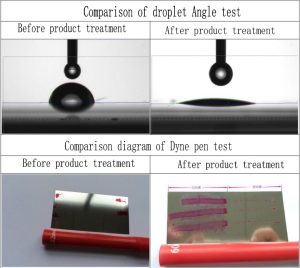

Improve the hydrophilicity of the product

Improve product surface adhesion

Processing before printing and bonding

Environmental protection technology, low temperature plasma, increase printing, dispensing, coating and other bonding effect

Dyne pen test: The Dyne pen is perpendicular to the surface of the material to be tested, and a straight line is drawn uniformly on the surface. If it is straight and does not shrink within 2-3 seconds, it indicates that the surface tension of the material has reached the tension value of the test pen. If the tip of the pen is broken and condensed into small droplets, it indicates that the test pen tension value has not been reached.

plasma surface treatment machine,Product adhesion improved,Surface treatment before bonding

Aviation industry

Plasma cleaning applications

With the development of the aviation industry, manufacturers will be looking for products with longer life, more reliable quality and lower cost. Previously, aircraft masks and strips were made of aluminum alloy, but now, these parts are mainly made of carbon fiber reinforced plastics. Plasmas play a big role in this. Carbon fiber reinforced plastic surface stability is better, so that the bonding and spraying process presented a more perfect state

Metal industry

(Whether it’s the metal accessories we wear or the metal tables and chairs we use in our homes, they may all have plasma treated surfaces. Nowadays, people are becoming more and more sophisticated in product design. Manufacturers in order to meet the needs of consumers will produce a variety of beautiful and durable metal products to attract the market, it can be said that plasma surface treatment of materials has infiltrated into our lives, in the past 30 years, low temperature plasma is widely used to change the mechanical properties of the surface of metal materials, plasma surface treatment of metal is :1. The friction and corrosion resistance of iron and steel alloys can be improved by ion beam nitrizing. 2. When ions are injected into metal surface, metal solid solution and sediment can be formed, so the hardness and wear of metal materials can be improved

Medical industry

Medical materials refer to inanimate materials used in contact with biological tissues to form functions. They are very good auxiliary materials in medical treatment, including polymer materials, metals, ceramics, glass or composite of various materials, etc., which are widely used in artificial organs, surgical repair, dental materials, cladding materials, orthopedic devices and medicine. Functional and mechanical properties, these materials are very good, but good biocompatibility is also quite critical, using plasma surface modification method can make them good compatibility, plasma only on the surface of a thin layer of treatment, does not change the performance of the material, and sterilization effect. So plasma surface treatment is becoming more and more widely used in medical materials.

Household appliance industry

Surface coating, spraying and bonding processes of daily necessities and household appliances. Plasma pretreatment can improve the bonding and coating quality of products

Plastic industry

Plastic, rubber, metal and other pretreatment before bonding, improve the surface adhesion, mobile phones, computers, toys and other plastic shell spray pretreatment, improve the surface adhesion

Packaging industry

In the field of printing and packaging applications, perhaps in the plasma surface treatment before what is not much known to the public, in fact, we very early began to use corona discharge, flame treatment surface modification method, that is, the most common form of discharge in the ionosome – dielectric barrier discharge (DBD) but now low temperature plasma processor has been widely used in the packaging industry, Change the printability of the packaging surface and the adhesion of the composite surface, plasma processing function for UV, coating, glazing, polymer and other materials surface treatment; Professional improve coated paper, glazed paper polishing, gold and silver card, aluminum plated paper, UV, OPP, PP, PET and other color boxes, color box surface paste box fastness; Eliminate all kinds of packaging box opening problem. Improve work efficiency, reduce grinding pollution, eliminate paper powder pollution of box paste machine, save consumables, save glue cost

Photoelectric glass and electronic industry applications

All kinds of glass surface cleaning, improve the glass surface hydrophilicity, optimize the plating, printing, bonding and spraying technology;

@ Flexible and non-flexible printed circuit board contact cleaning, LED fluorescent lamp “contact” cleaning and improve the surface adhesive firmness;

Precision glass

@ Electronic components, PCB cleaning, IC surface cleaning, activation enhancement binding, etc.; @LCD LCD screen terminal surface before plasma cleaning;

Electronic industry

Electronic components processing of plasma pretreatment, PCB cleaning, electrostatic removal, LED support, IC surface cleaning and bonding

Automobile industry

EPDM rubber strip spray lubrication coating or flocking glue pretreatment process; Plasma surface pretreatment technology is used for car headlight bonding, brake pad wiper, hood, instrument and bumper