- 描述

- 查询

等离子清洗机,Carton plasma surface treatment machine,Adhesion processor,Electronic ion processor

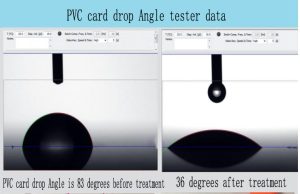

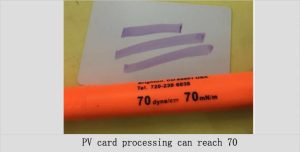

活化表面提高产品亲水性

提高产品表面附着力

印刷粘合前处理

环保技术, 低温等离子体, 增加印刷, 配发, 涂层及其他粘合效果

等离子清洗机,Carton plasma surface treatment machine,Adhesion processor,Electronic ion processor

低温等离子表面处理技术简介

The energy of particles in low-temperature plasma is generally about several to ten electron volts, 大于高分子材料的键能 (several to ten volts), and can completely break the chemical bonds of organic macromolecules and form new bonds, but it is far lower than high-energy radioactive rays, which only involves the surface of the material and does not affect the performance of the matrix. In low-temperature plasma in non-thermodynamic equilibrium state, electrons have high energy, which can break the chemical bonds of molecules on the surface of materials and improve the chemical reactivity of particles (greater than that of hot plasma), while the temperature of neutral particles is close to room temperature. These advantages provide suitable conditions for surface modification of heat-sensitive polymer polymers. 通过低温等离子表面处理, 材料表面发生多种物理、化学变化, or produce etching and rough process, 或形成致密的交联层, 或引入含氧极性基团, 从而使亲水性, 凝聚力, 可染色性, 生物相容性和电性能得到改善. By treating the surface of the material under the appropriate technological conditions, the surface morphology of the material has changed significantly, and a variety of oxygen-containing groups have been introduced to make the surface change from non-polar, 粘度难以达到一定极性, 易粘性和亲水性, which is conducive to bonding, coating and printing. 然而, because corona can only be carried out between two adjacent parallel electrodes, and the distance should not be too large, the corona processing method is not suitable for dealing with the surface polarization problem of three-dimensional objects. The weakness is that all polymers are flammable and have a low melting point if treated by pyrofusion. When organic materials are placed under high temperature flame, they will deform, discolor, rough surface, burn and emit every gas due to high temperature treatment. And the processing technology is difficult to master. The low temperature plasma flow process is the best method to modify the surface of 3D object. The common principle is shown in the figure. By applying AC high frequency and high voltage at both ends of the electrode, the air between the two electrodes generates gas glow discharge and forms an isoionization zone. Plasma is blown by air currents to reach the surface of the object being treated.

等离子清洗机,Carton plasma surface treatment machine,Adhesion processor,Electronic ion processor

Plasma application horizon

Electronic glass, printing jet code, plastic rubber, electronic packaging

包装行业

Professional to improve the film paper, glazed paper, polished, 金卡和银卡, 镀铝纸, 紫外线, OPP, 聚丙烯, PE and other color boxes, 彩盒表面贴盒牢度;

电子行业

Electronic components processing plasma pretreatment, PCB cleaning, removal of static electricity, LED support, IC surface cleaning and bonding.

汽车行业

Plasma surface pretreatment process is adopted for car headlight bonding, brake pad, wiper, 兜帽, 仪表和保险杠;

Printing code industry

Plasma pretreatment before pad printing, screen printing and jet coding on the surface of composite materials such as plastic, metal and boyao can improve the adhesion of material surface to ink

精密玻璃

All kinds of precision glass, spraying, 印刷, bonding before treatment. LCD IC binding before the terminal surface cleaning, improve the glass surface cleanliness and hydrophilicity:

塑料行业

塑料, 橡胶, gold and other pretreatment before bonding, 提高表面附着力; · Pretreat the plastic shell of mobile phones, 电脑, toys and so on before painting to improve the surface adhesion

等离子清洗机,Carton plasma surface treatment machine,Adhesion processor,Electronic ion processor

航空工业

等离子清洗应用

随着航空业的发展, manufacturers will be looking for products with longer life, more reliable quality and lower cost. Previously, aircraft masks and strips were made of aluminum alloy, 但现在, 这些部件主要由碳纤维增强塑料制成. 等离子体在这方面发挥着重要作用. Carbon fiber reinforced plastic surface stability is better, so that the bonding and spraying process presented a more perfect state

金属行业

(Whether it’s the metal accessories we wear or the metal tables and chairs we use in our homes, they may all have plasma treated surfaces. 如今, people are becoming more and more sophisticated in product design. 厂家为了满足消费者的需求就会生产出各种美观耐用的金属制品来吸引市场, 可以说,材料的等离子表面处理已经渗透到我们的生活中, in the past 30 年, 低温等离子体广泛用于改变金属材料表面的力学性能, 金属的等离子表面处理是 :1. 离子束渗氮可提高钢铁合金的摩擦和耐腐蚀性能. 2. When ions are injected into metal surface, metal solid solution and sediment can be formed, 从而提高金属材料的硬度和耐磨性

医疗行业

医用材料是指与生物组织接触而形成功能的无生命材料. 它们是很好的医疗辅助材料, 包括高分子材料, 金属, 陶瓷, 玻璃或各种材料的复合材料, 等等, 广泛应用于人造器官, 手术修复, 牙科材料, 包层材料, 骨科器械和药品. 功能和机械性能, 这些材料非常好, 但良好的生物相容性也相当关键, 采用等离子表面改性方法可以使它们具有良好的相容性, 等离子仅在表面进行一薄层处理, 不改变材料的性能, 和杀菌效果. 因此等离子表面处理在医用材料上的应用越来越广泛.

家电行业

表面涂层, 日用品、家用电器的喷涂、粘接工艺. 等离子预处理可提高产品的结合和涂层质量

塑料行业

塑料, 橡胶, 金属等粘接前的预处理, 提高表面附着力, 手机, 电脑, 玩具等塑料外壳喷涂预处理, 提高表面附着力

包装行业

在印刷包装领域的应用, 或许在等离子表面处理之前,公众并不多知道什么, 当使用摆杆 Sunny 测试仪测量涂层厚度时, 我们很早就开始使用电晕放电, 火焰处理表面改性方法, 那是, 离子体中最常见的放电形式 – 介质阻挡放电 (DBD) 但现在低温等离子处理机已经广泛应用于包装行业, 改变包装表面的印刷适性和复合表面的附着力, UV等离子处理功能, 涂层, 玻璃窗, 聚合物及其他材料表面处理; 专业改善铜版纸, 釉面纸抛光, 金卡和银卡, 镀铝纸, 紫外线, OPP, 聚丙烯, PET等彩盒, 彩盒表面贴盒牢度; 消除各类包装盒开启问题. 提高工作效率, 减少磨削污染, 消除糊盒机纸粉污染, 节省耗材, 节省胶水成本

光电玻璃及电子行业应用

各类玻璃表面清洗, 提高玻璃表面亲水性, optimize the plating, 印刷, 粘合和喷涂技术;

@ Flexible and non-flexible printed circuit board contact cleaning, LED日光灯 “接触” 清洁并提高表面粘合牢固度;

精密玻璃

@ Electronic components, PCB cleaning, IC表面清洗, 激活增强结合, 等等; @LCD LCD screen terminal surface before plasma cleaning;

电子行业

Electronic components processing of plasma pretreatment, PCB cleaning, electrostatic removal, LED support, IC surface cleaning and bonding

汽车行业

三元乙丙胶条喷涂润滑涂层或植绒胶预处理工艺; 等离子表面预处理技术用于汽车大灯粘接, 刹车片雨刮器, 兜帽, 仪表和保险杠

等离子清洗机,Carton plasma surface treatment machine,Adhesion processor,Electronic ion processor

1. 等离子表面处理机有什么作用 (清洗机) 做?

等离子表面处理机利用电流产生常温等离子体作用于牙膏盒等各种包装的舌部表面, 香烟盒, 酒盒、礼品盒. 经过加工和粘合后, 不会有脱胶的问题, 你可以用普通胶水粘贴盒子, 大大降低胶水成本.

贵公司是否使用全自动糊盒机? 等离子表面处理机可与糊盒机配套使用.

2. 等离子表面处理机有哪些产品?

一种: 目前市场上常见的是单喷嘴等离子表面处理机. 并且我公司开发了双喷嘴等多项产品, 三喷嘴, 旋转喷嘴, 等等. 我们的专业R & D团队也可以专攻R & 根据客户需求研发生产’ 需要.

3. 等离子表面处理机主要功能及优点?

一种: 1. 喷涂等离子流呈中性, 可以是多种聚合物, 玻璃, 金属, 半导体, 橡胶, PCB线路板等材料的表面处理.

2. 等离子表面处理机处理后去除碳化氢污垢, 比如油脂, 辅助添加剂, 有利于粘合, 耐用稳定的性能, 保留时间长.

3 等离子体温度忽高忽低, 针对不同材质选择不同温度等离子, (功率大小可调节) suitable for those surface materials sensitive to temperature products.

4. Every type of atmospheric pressure equipment has on-line function! Can be directly installed on the production line, with field equipment online operation processing! 相对于磨边机的反向操作, 大大提高工作效率.

5. 仅消耗空气和电力, 所以运行成本低,操作更安全.

6. 干法处理无污染, 无废水, 符合环保要求; 并取代传统磨边机, 杜绝纸粉纸棉对环境及设备的影响.

7. 经过等离子表面处理机处理后, 可以用普通胶水来粘盒子, 降低生产成本. Plasma processor introduction: plasma technology is a good solution to the coated paper, 上光纸, 铜版纸, 镀铝纸, 紫外线涂层, 聚丙烯, PET与其他材料粘合不牢, or unable to bond the problem. 解决很多企业过去采用传统局部涂装的问题, 局部玻璃, 平面磨削或切贴线, 使用特殊胶水改进粘合方法.

等离子技术使用普通水性胶后可以很好的粘合, 不再因为不同的纸板而更换不同的胶水. 不仅有效解决了糊盒问题, 糊盒生产工艺问题, 也对企业的流程有很好的保障, 效率, 质量.

4. 等离子处理工艺可实现选择性表面改性:

1. 激活: 大大提高表面润湿性, 形成活性表面

2. 打扫: 去除灰尘和油污, 精细清洗、除静电

3. 涂层: A functional surface is provided by a surface coating treatment

4. Improve the adhesion ability of the surface

5. Improve the reliability and durability of surface bonding

5. Application Field:

各类玻璃表面清洗, 提高玻璃表面亲水性, 优化玻璃镀膜, 印刷, 粘合和喷涂技术;

柔性和非柔性印刷电路板触点清洁, LED日光灯 “接触” 清洁并提高表面粘合牢固度;

Electronic components, PCB cleaning, IC表面清洗, 激活增强结合, 等等;

Plasma cleaning before LCD terminal lamination;

Automotive industry application

Automotive EPDM seal strip, flocking and pre-coating pretreatment instead of using base coating;

Car lamp base, groove, brake pad, bumper bonding, plasma pretreatment before spraying;

Pre-treatment of automobile anti-puncture tire before gluing;

New energy vehicle lithium battery electrode plate welding, coating surface activation, cleaning, 等等;

Plastics industry application

聚丙烯, PVC, 宠物, 个人电脑, 体育, PTFE and other types of plastic materials spraying, 印刷, electroplating, bonding and flocking before treatment.

All kinds of plastic, 硅酮, 橡胶, metal and other materials spraying, 印刷, electroplating, bonding before surface modification, removal of surface pollutants;

Mobile phones, 电脑, toys and other plastic shell printing, spray pretreatment, improve surface adhesion;

Plastic cosmetic bottle preprocessing before printing, improve the surface adhesion can prevent word falling off and improve product quality;

Packaging industry application

专业改善铜版纸, 上光纸, 抛光, 金卡和银卡, 镀铝纸, 紫外线, OPP, 聚丙烯, PET等彩盒, 彩盒表面贴盒牢度;

Plasma pretreatment of milk powder cans and beverage cans before welding;

Printing and coding industry applications

Plasma pretreatment before pad printing, screen printing and jet coding on the surface of plastic, 金属, glass and other composite materials to improve the adhesion of material surface to ink;

体育, PTFE, silicone rubber wire and cable coding before processing;

PVC, 宠物, ABS smart card pre-processing;

Appliance industry application

Plasma activation before coating, spraying and bonding of daily necessities and household appliances can improve the surface adhesion and bonding force of products.

Health pot heating plate plasma cleaning enhanced glue adhesion, firmness, 等等;