- Description

- Inquiry

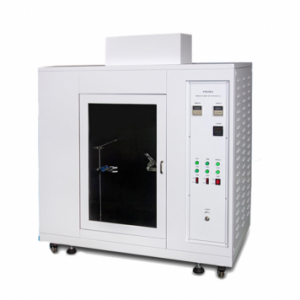

LS-919 Automatic Building Material Non-combustibility Test Furnace

Product features

- Dual control mode: the operation can be controlled on the touch screen or the computer, and the operation mode can be switched arbitrarily;A device can operate several computers at the same time, several computers can be online at the same time, LAN sharing can be achieved;

- With automatic lofting function, the sample can be put into the furnace automatically after the temperature is stable, and the sample basket can be rotated 90 degrees automatically after the outlet of the furnace, when the sample is changed.Automatic lofting process can be stopped at any time, the sample basket can be returned to the initial position automatically;

- Adopt microcomputer technology and silicon controlled technology to adjust the temperature of furnace body through power

- 4. High degree of automation, display and record the temperature of furnace, sample center and sample surface during the test, and the operation prompt will pop up automatically for the test step

- 5. It can query the historical curve and automatically judge the temperature balance

- 6. The test process is safe, reliable and easy to operate

- 7. The customized mold is used to form the refractory furnace with good heat insulation performance

- 8. Use high quality strip heaters, furnace temperature may rise to 900 ℃

- 9. PLC+NAbview professional software can display the temperature inside the furnace, sample center temperature and sample surface temperature curve in real time, which can realize automatic control, data collection and processing, data storage and output measurement results.

- 10. Observation mirror is equipped on the top to facilitate users to safely observe the burning state of samples in the furnace.

LS-919 Automatic Building Material Non-combustibility Test Furnace

Design Standard

GB/ T 5464-2010 GB/T8624 ISO1182 fire reaction test for building products-non-combustible test

LS-919 Automatic Building Material Non-combustibility Test Furnace

Main Technical Specification

| Furnace specifications | Φ40cm Height 1.5m |

| 80/20 Ni-cr resistance specification | Thickness 0.2mm、width 3mm |

| Automatic sampling device | L 8cm,W 8cm,H 83cm |

| Sample basket travel track | W 2cm,L 38cm |

| Range of extension of the observation mirror | Φ45×50(mm) |

| heating furnace tubes | Inner diameter Φ75mm±1mm,out diameter Φ90mm±1mm, height 150mm±1mm,rate of power 2KW |

| thermocouple | Nickel-chrome-nickel-silicon armored thermocouple, outer diameter 1.5mm, wire diameter 0.3mm, electric wire power: 2KW |

| Temperature stabilization time in furnace | RT-750℃ Stable to do test,about 1 hour |

| Power | AC220V±10%, 50Hz,Current≤10A; |

| Stability time | RT-750°C≤1h |

| Temperature measurement accuracy | ≤±0.5℃ |

| heating power | 1.5KW |

| Power heating voltage | 0~100 V Adjustable |

| Place the thermocouple in the furnace, the sample center thermocouple and the sample surface thermocouple | |

| A thermocouple scanning device that rotates and lifts 360 degrees | |

| Stainless steel tapered air stabilizer and cylinder guide cover | |

| The software automatically controls the heating rate and the furnace body temperature in stages | |

| Heating source is preheating to 750±5degree,,max temp in furnace 900degree,furnace temperature 750±5°C,temperature drift 10min not exceed 2℃ | |

| A central copper hammer device in the furnace is required to calibrate the temperature in the furnace. The connected curves shall be within the range of the curve required by the standard | |

| The furnace wall temperature needs to be calibrated with a thermocouple, and the temperature of the furnace wall needs to be calibrated with a scanning thermocouple at three equal angles | |

| The software includes the current regression to judge the temperature balance conditions | |

LS-919 Automatic Building Material Non-combustibility Test Furnace

Parts list in package

| Furnace | 1set |

| Control box | 1set |

| basket | 1pcs |

| Low plate | 1pcs |

| Connect wire | 1pcs |

| Operation manual | 1pcs |

| certificate of quality | 1pcs |