- Description

- Inquiry

Flexo Ink Proofer Flexo Printing Ink Flexographic waterborne, UV ink, lithographic

Main Technical Parameters

Flexo Ink Proofer Flexo Printing Ink Flexographic waterborne, UV ink, lithographic

Control voltage: 24VDC Power: 0.5K

Inking mode: pipette Ink Dropping

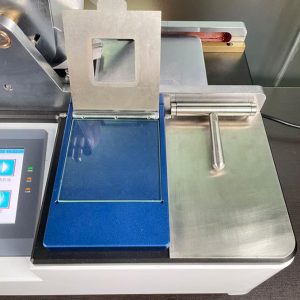

Proofing material thickness: 0.01-2mm (flexural material)

Proofing material size: 100x405mm

Printing area:90*240mm

Plate area: 120x405mm

Plate thickness:1.7mm thick flexographic adhesive 0.3mm

The pressure of the roller and the net roller is regulated by the motor and has the scale display pressure.

Roller and impression pressure: adjustable, with scale indicating pressure.

Printing speed is adjustable: 10-130 M / min.

Specification of ceramic mesh roll: Phi 80x120mm

The number of ceramic mesh rollers: Standard 500 lines (70- 1200 lines can be customized).

Suitable for printing ink: Flexographic waterborne, UV ink, lithographic, letterpress or UV ink.

Suitable proofing materials: paper, plastic film, non-woven fabrics, napkins, gold and silver cardboard, etc.

Appearance size: 550x515x420mm

Net weight of instrument: 88KG

Application scope and characteristics

Flexo Ink Proofer Flexo Printing Ink Flexographic waterborne, UV ink, lithographic

1. The instrument can be coated, solid color, dot pattern proofing.

2. Ceramic roller rotates the ink evenly first, then the printing material is printed. The printing plate cylinder starts to rotate synchronously for one week to complete the proofing work. The ceramic roller, the printing material cylinder and the printing plate cylinder run synchronously to ensure the proofing quality.

3. Using private clothes and stepping motors, touch screen control, so that operation is more simple, more precise control.

4. Scraper, ceramic roller, printing plate roller, printing drum four structure can adjust the pressure, flexible adjustment;

5. Net roller, scraper cartridge disassembly and cleaning is simple and convenient.

6. The installation of printing materials, installation of printing plate and cleaning plate is simple and convenient.