- Description

- Inquiry

CNC-3020A CNC-4030A CNC-5040A Small CNC Measuring Machine

Use

Small CNC measuring machine is a high performance measuring equipment developed by our company.It can realize high efficiency and accurate measure large quanities of workpieces.It is suitable for the inspection and quality control of precision parts.In the machinery,electronic,hardware,plastics and other industries have been widely used.

CNC-3020A CNC-4030A CNC-5040A Small CNC Measuring Machine

Features

1.High precision overall measurement,Z axis CNC control.

2.High precision and high strenght machine:00 marble base/upright column/worktable,high precision and good stability.

3.XYZ thress axis imported precision V type guide rail/imported grinding level ball screw drive system,long service life,good stablity.

4.High precision grating ruler 0.5μm.

5.WM continuous zoom optical lens,different frames,different magnification,no need zoom correction.

6.HD japanese SONY CCD camera,high quality measuring screen.

7.Auxiliary focusing measurement,optical measuring altitude and flatness,and can be equipped with the British RENISHAW contact probe.

8.Program controlled three ring eight area surface light,LED profile light,coaxial light.Different products with different color light.

9.Equipped with Control handle,easy to opreate at any place.

10.Combined with imported software,3D measuring software is developed to improve the bondary resolution capability.

CNC-3020A CNC-4030A CNC-5040A Small CNC Measuring MachineCNC-3020A CNC-4030A CNC-5040A Small CNC Measuring Machine

Specification

| Machine Model | CNC-3020A | CNC-4030A | CNC-5040A | |

| Work table | X/Y axis travel mm | 300*200 | 400*300 | 500*400 |

| Z axis travel mm | Effective space is 245mm,focusing stroke is 200mm,work distance is 95mm | |||

| Mental table size mm | 450*350 | 550*450 | 700*600 | |

| Glass table size mm | 330*230 | 650*650 | 530*430 | |

| Drive type | X/Y/Z axis precision linear guide,Z Axis grinding ball screw drive. | |||

| Measure drive system | Optical scale resolution:X/Y/Z axis 0.0005mm(0.5μm) | |||

| Measure accuracy:≤3μm+L/200 reapeatability accuracy:≤3μm+L/200 | ||||

| Z axis high performance servo motor,double closed loop control system. | ||||

| Image System | Camera:Japanese SONY CCD video magnification 30-230X | |||

| Len:high definition zoom lens/Continuous magnification 0.7-4.5X Can match 0.5X objective lens,total magnification:15-115X Can match 2X objective lens,total magnification:60-460X | ||||

| Light system | Surface light and projection light,cold light,long life,brightness adjustable. | |||

| Machine external dimension | 700*850*1650 | 800*900*1650 | 900*1050*1650 | |

| Weight kg | 330 | 400 | 500 | |

Software introduce

WM – ME 3 d measurement software main functions are as follows:

(1) Measuring element:

Can measure the 12 kinds of elements, such as point, line, circle, arc, ellipse, rectangle, trough, o-rings, distance, Angle and open cloud line, closed cloud line).

Features:

Measurement method variety (automatic discriminant, mining point measurement, comparison, tolerance contrast measurement. Preset element), can satisfy differentcustomers’ needs, greatly improve the ease of use and measuring precision.

There are many single point sampling method: the mouse point, cross line edge point, amplified by points.

Closed to measure the perimeter of the cloud line, area and center of gravity, the use ofthree interpolation algorithm, for the most accurate measuring method of cloud line.

Can undertake box to choose measurement more round, fast and accuratemeasurement of multiple round at a time.

The measured data can be saved as a DXF file, or. BMP images, and the user programformat.

(2) Macro measurement function

Macro measurement function is that will be some measure, command associated witha button. Click on the buttonthat starts the macro measurement function, macro measurement function automatically completes the tectonic movement, decrease the times of user mouse operation and improve the work efficiency.

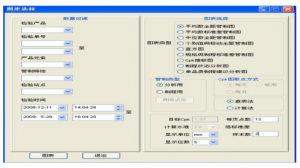

Note: macro measurement is different from the user program function, macro measuredoes not record source, coordinate position measurement condition, etc. Run themacro function, also do not move the workbench, polishing, etc. 16 software provides aset of macro measure function, the user can edit the macro measurement functionbutton icon. Macro function interface is as follows:

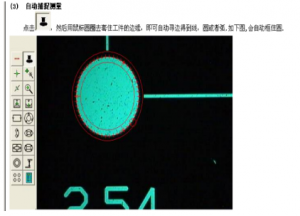

(3) Automatic capture measurement

Click, and then use the mouse to circle to the edge of the workpiece, can automatically find edgeline, circle or arc. The following figure, will automatically be framed round.

(4) element structure:

Elements to construct powerful. MEGA structure provide 10 kinds of 2 d elements method (“translation “, “rotation” and “extraction”, “combination”, “parallel” and “vertical”, “mirror”, “symmetry”, “intersection”, “tangent”) tectonic geometry elements. MEGA elements of 2 d structure makes ithard for users to easily cope with some measure of elements, so as to improve the work efficiency.

(5) Autofocus function

Provide a precise focus and shooting function and through measuring height value focus, or thecurrent is obtained by af point coordinates.

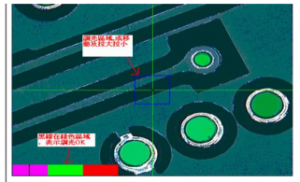

(6) Auxiliary dimmer

That move light indicator, instructs the user when is the best time to light intensity, avoid themeasurement error brought by the due to the lighting, improve the measuring accuracy andmeasuring efficiency.

(7)Graphics functions:

Have perfect image processing and display function (local amplification, scaling, translation, window display, full screen), makes the measurement more image, intuitive, easy to user operation. Rolling middle mouse button, zoom in on graphics, hold key notto put in the moving the mouse, the mobile graphics.

(8) Tagging function:

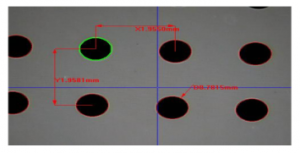

Can directly in the plot and the elements of the image graphics on the Angle,distance, distance of X direction and Y direction distance and radius of circle (arc),round (arc) diameter, arc length. The user be clear at a glance.

Image window and drawing window can synchronize display measurementelements and annotations. Images can be hidden window drawing graphics, cansynchronize to delete, select image window and 2 d graphics window graphic elements. Below to indicate two round X direction and Y direction distance, and the radius of thecircle.

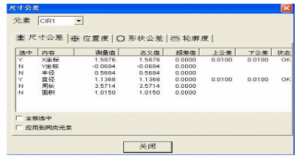

(9) Tolerance

Improve the dimensional tolerance of computing power. Can set the defaulttolerance zone.

Conform to the national standard of the form tolerance capacity, can calculate theshape tolerance, really straight degree, circle, arc roundness.

Position tolerance calculation contains position degree, parallel degree, verticaldegree, slope and concentricity, degree of symmetry. Out-of-tolerancealarmautomatically, and with red warning.

Round size tolerance input dialog is illustrated below.

(10) DXF file import programming

After importing the DXF file, the software will prompt the user operation step by step, when establishthe workpiece coordinate system, the DXF file user program to complete the import. The softwarewill automatically generate value in the name of the element name. When running a user program, will produce DXF file and image texture contrast.

(11) Reporting features

Measurement data can be exported to Excel, Word,AutoCAD, TXT.

When running the user program, but will import data in rows or columns way to Excel.

Import to the report, they can choose whether to export the graphics and bitmap.

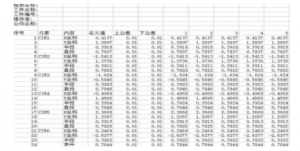

Pictures, below is the same workpiece measurement after five times, automatic export to Excel inthe report.

(12)Online SPC functions

MEGA 2 d provide independent, professional SPC software, for subsequentprocessing of measured data.

Software and SPC software seamless connection, measurement software aftercompletion of measurement data imported into the SPC database automatically, without human input again, all the control limits set was done in measuring software, noneed to set the SPC software, thus greatly improve theefficiency. SPC providesprocess and analysis with the control charts. Provide control charts are: average rangecontrol chart, the average standard deviation control charts, the median range controlchart, individual values and moving average control chart, histogram, CPK graph,specification standard deviation control charts, the process standard deviation controlcharts, standard deviation comparison chart, process suggested analysis diagram, etc. To generate graphics can use eight decision rules for decision. Their charts and datacan be printed and imported into Excel.

Chart to choose the chart type dialog box.

(13) Help system

WM – ME 2 d provides a complete help system. Help users are not familiar withsoftware, quickly master the use of the software.