- 기술

- 문의

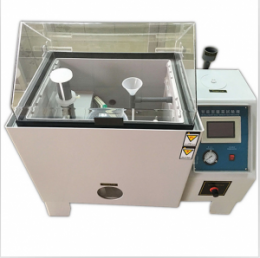

BGD 880-S 프로그래밍 가능한 염수 분무(안개) 캐비닛

기술

The salt spray test is a standardized test method used to check corrosion resistance of coated samples. Coatings provide corrosion resistance to metallic parts made of steel, zamak or brass. Since coatings can provide a high corrosion resistance through the intended life of the part in use, it is necessary to check corrosion resistance by other means. 염수 분무 테스트는 보호 마감재로 사용하기에 적합한지 예측하기 위해 코팅된 샘플에 부식 공격을 일으키는 가속 부식 테스트입니다.. 부식 생성물의 출현 (산화물) 일정 시간이 지난 후 평가됩니다.. 테스트 기간은 코팅의 내식성에 따라 달라집니다.; 코팅의 내식성이 높을수록, 부식 징후가 나타나지 않고 테스트 기간이 길어질수록.

Salt spray testing is popular because it is cheap, quick, well standardized and reasonably repeatable. There is, however, only a weak correlation between the duration in salt spray test and the expected life of a coating (especially on hot dip galvanized steel where drying cycles are important for durability), since corrosion is a very complicated process and can be influenced by many external factors. 그럼에도 불구하고, salt spray test is widely used in the industrial sector for the evaluation of corrosion resistance of finished surfaces or parts.

The apparatus for testing consists of a closed testing chamber, where a salted solution (mainly, a solution of 5% sodium chloride) is atomized by means of a nozzle. This produces a corrosive environment of dense saline fog in the chamber so that parts exposed in it are subjected to severely corrosive conditions.

Tests performed with a standardized 5% solution of NaCL are known as NSS (neutral salt spray). Results are represented generally as testing hours in NSS without appearance of corrosion products (예를 들어. 720 h in NSS according to ISO 9227). Other solutions are acetic acid (ASS 테스트) and acetic acid with cooper chloride (CASS test), each one chosen for the evaluation of decorative coatings, such as electroplated copper-nickel-chromium, electroplated copper-nickel or anodized aluminium.

Some sources do not recommend to use ASS or CASS test cabinets interchangeably for NSS tests, as it is claimed that a thorough cleaning of the cabinet after ASS or CASS test is very difficult. ASTM does not address this issue, but ISO 9227 does not recommend it and if it is to be done, advocates a thorough cleaning.

Biuged offer various Salt Spray Cabinets from 150L capacity to customized cabinets according to different requirements. All of cainets not only can run NSS test but also CASS or ASS test

BGD 880-S 프로그래밍 가능한 염수 분무(안개) 캐비닛

| Structure Feature | |

| Chamber Structure | ◆Cabinets are made of imported 5mm PVC ploy plate(Nanya, Taiwan), max. durable temperature is 85 ℃ ◆Cabinet sealing cover is made of European 6mm acrylic sheets ◆Salt solution reservoir equipped with water level is designe in the chamber,청소하기 쉬운 ◆Humidifying tower is made of SUS 304#, endurable high pressure and good thermal insulation effect. ◆Specimen supports designed specially ensure a adjustable position angle for each specimen in order to get a uniform fog and a big specimen capacity. ◆Use water to seal working room, ensure the corrosion fog not to leak. ◆Electric system is separated from water system, avoid water to enter electric control box to damage accessories ◆There is a hole used to drain off fog at the back and bottom of chamber, its damater is 48mm, just used other pipe to connect this hole to drain off the fog from the working room |

| Chamber Sealing Cover | V shape , the top ange is 100º, prevent condensate water during the test from dropping to specimen surface and affect testing results. |

| Atomizing Tower | In order to ensure the working room to get uniform fog while spraying, this chamber use a special structure glass nozzle to atomize salt solution absolutely, then fog enter a subuliform tower installed in the working room and spray to all working room uniformly. The installation height of atomizing tower can be adjusted to control spray fog amount precisely. |

| Fog Collector | Fog collectors are tapered funnels whose diameter are 100mm and installed in the working room.At the bottom of the funnel, there is a silicone pipe which connect with graduated cylinder installed outside. These graduated cylinders are used to monitor spray fog amount |

| Heating 체계 | For working room, heating tube is made of titanium alloy, water vapour heat the working room under the control of P.I.D |

| Salt Solution Supply | The salt solution prepared well is stored in salt solution reservoir, and flow into supplying container under the water level difference. This supplying container is equipped with an automatic water leveling device which can control automatically the max. water level to keep a certain distance with spray nozzels. |

| Humidifying Tower | Is made of SUS304# stainless steel, and its temperature can be set from RT-63℃ and heating up time≤60 min, can add water automatically.Water level is monitored and system would alarm once exceed set level value. |

| Heater | Armoured titanium alloy electric heating tube(at the bottom of working room) Armoured SUS316# electirc heating tube(Humidifying tower) Heating controlling method:SSR |

| Fog Spray System | |

| Spray Fog 원칙 | Use Bernouilli’s principle to absorb salt solution then atomize it Air Compressor→Oil-water Separator(first)→Air Storage Tank→Relief Valve→Total Solenoid Valve→Oil-water Separator(second)→Saturator→Pressure Regulating Valve→Solenoid Valve for spraying→Spray Nozzle |

| Spray Nozzle | made of special glass, can control fog amount and spraying angle |

| Spray 압력 | Spray pressure can be adjusted from 0.07MPa to 0.17 MPa, in order to make sure the spray pressure generated from spray nozzle be within the range of standard requirments, it is divided into two steps, adjust air pressure to 0.2MPa to 0.3 MPa as the first step, then adjust to 0.07MPa to 0.17 MPa under the second step |

| Drain away Fog | Can drain away fog by manual or set a program to do it. Feed fresh compressed air to working room then drain away the fog of the working room quickly |

| Electronic Control System | |

| 제어 장치 | E5CC digital display temperature controller imported from Omron, Japan. control working room and humidifying tower temperature |

| Working Method | Worked at fixed value, starting and stopping is timed |

| Setting Method | English menu, input data by key |

| 디스플레이 해결 | 0.1℃ (temperature) |

| 시간제 노동자 | Digital display , can set second, minute, 10 분, 시간, 10 시간 , max.is 9,999 시간, min.is 1 둘째 |

| Programme 제어 장치 | Digital display , spray time and interval time can be set freely, infinite cycle. Timing unit: 둘째, minute, 10 분, 시간, 10 hours(switch freely) max.is 9,999 시간, min.is 1 둘째. |

| Safety Protection Device | |

| Cabinet | Over temperature protection, water leakage protection |

| Humidifying Tower | Over temperature protection, water leakage protection |

| Heating 체계 | Anti-dry safety protection: all heaters of the cabinet are fitted with a temperature limit protection, which can effectively solve the problem of overheating , heating tube dried , abnormal water supply, short circuit and overload etc. |

| Water Supply | Water level protector for working room, low water level protector for humidifying tower |

| 힘 | Earth leakage protection, overload and short-circuit protection |

D50,D55,D65,D75,F1,F2,F3,F4,F5,F6,F7,F8,F9,F10,F11,F12,CMF

ISO 4611 《Plastics—Determination of the effects of exposure to damp heat, water spray and salt mist》

ISO 7253 《Paints and varnishes — Determination of resistance to neutral salt spray (안개) 》

ISO 9227 《Corrosion tests in artificial atmospheres — Salt spray tests》

ASTM B 117 《Standard Practice for Operating Salt Spray (Fog) Apparatus》

ASTM B368 《Standard Test Method for Copper-Accelerated Acetic Acid-Salt Spray (Fog) Testing (CASS 테스트) 》

ASTM B 380 《Standard Test Method for Corrosion Testing of Decorative Electrodeposited Coatings by the Corrodkote Procedure》

ASTM G85 – 11 《Standard Practice for Modified Salt Spray (Fog) Testing》

ASTM D 1735 《Standard Practice for Testing Water Resistance of Coatings Using Water Fog Apparatus》

에서 50021 《Salt Spray Testing》

BGD 880-S 프로그래밍 가능한 염수 분무(안개) 캐비닛

D50,D55,D65,D75,F1,F2,F3,F4,F5,F6,F7,F8,F9,F10,F11,F12,CMF

■ Working Room Temperature Range:RT~50℃

■ Humidifying Tower Temperature Range:RT~63℃

■ Temperature Uniformity:≤ ±2℃(No-load)

■ Temperature Stablility:≤ ±0.5℃(No-load)

■ Temperature Devitation of Working Room:±1.0℃

■ Temperature Increasing Rate:RT→55℃ less than 60 minutes(working room);RT→63℃ less than 60 minutes(saturated barrel)

■ Compressed Air Supply:Customer should prepare a air compressor which can offer clean,waterless and oilless compressed air,0.4MPa~0.8MPa pressure

| 주문정보 → 기술적인 매개변수 ↓ | BGD 880/S | BGD 881/S | BGD 882/S | BGD 883/S |

| Working Room Size(W×H×D),mm | 1000×650×720 | 900×500×600 | 1200×500×800 | 1600×800×1000 |

| Working Room Capacity(no including V shape cover) | 108 엘 | 270 엘 | 480 엘 | 800 엘 |

| V Shape Cover Volume | Appr. 50 엘 | Appr. 140 엘 | Appr. 250 엘 | Appr. 380 엘 |

| Overall Size(W×H×D),mm | 1150×1090×672 | 1550×1240×900 | 1980×1350×1100 | 2480×1450×1250 |

| Qua. of V Shape sample holder/pole | 4/6 | 6/12 | 8/16 | 10/22 |

| Tank capacity for Salt Solution | 15 | 25 | 40 | 45 |

| Collectors | 1 | 2 | 2 | 2 |

| 최대. Sample Capacity(15cm×7cm) | 28 개 | 70 개 | 108 개 | 120 개 |

| Method of Opening Cover | 처짐 시험기 | 처짐 시험기 | Pneumatic | Pneumatic |

| Total Power | 2.2 KW | 2.2 KW | 3.8 KW | 3.8 KW |

| Salt Solution Consumption | 15 L/d | 15 L/d | 25 L/d | 25 L/d |

| Water for heating Consumption | 30 L/d | 30 L/d | 40 L/d | 40 L/d |

| Compressed Air Consumption | 1미디엄3/h | 1미디엄3/h | 2미디엄3/h | 2미디엄3/h |

| 대리석 등 | 220V;50/60HZ | |||

영형ptional Accessories:

BGD 1356—Glass Spray Nozzle

BGD 2309—CR-4 Steel Panels for Calibration of Salt Spray(Conforms ISO 3574, 20 pcs for one package)