- 기술

- 문의

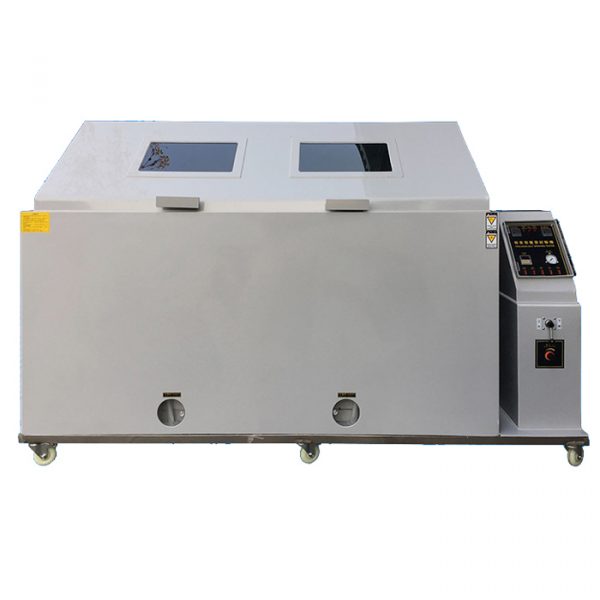

LS-207-1 ASTM B117 ISO 9227 염수 분무 시험기(200유형)

사용하다:

이 기계에는 코팅된 샘플의 내식성을 확인하기 위한 표준화된 테스트 방법이 있습니다.. 염수 분무 테스트는 보호 마감재로 사용하기에 적합한지 예측하기 위해 코팅된 샘플에 부식 공격을 일으키는 가속 부식 테스트입니다.. 부식 생성물의 출현 (산화물) 일정 시간이 지난 후 평가됩니다.. 테스트 기간은 코팅의 내식성에 따라 달라집니다.; 코팅의 내식성이 높을수록, 부식 징후가 나타나지 않고 테스트 기간이 길어질수록. 코팅에 따라 염수 분무 테스트에서 거동이 다르므로 결과적으로, 테스트 기간은 코팅 유형에 따라 다릅니다..

설계 표준:ISO 9227,GB/T 2423.17-1993 ,GB/T 2423.18-2000,GB/T 10125-1997,ASTM.B117-97

그는 H8502 ,IEC68-2-11,IEC68-2-52 1996 ,GB.10587-89,CNS.4158,CNS.4159,CASS,GB/T 12967.3-91 CASS

LS-207-1 ASTM B117 ISO 9227 염수 분무 시험기(200유형)

사양:

| 내부 크기 | 2000×1600×600(L×W×H)mm |

| 외부 크기 | 2750×1850×700(L×W×H)mm |

| Test room temperature | NSS ACSS 35℃±1℃/ CASS 50℃±1℃ |

| Pressure Barrel Temperature | NSS ACSS 47℃±1℃/ CASS 63℃±1℃ |

| Laboratory capacity | 1920엘 |

| Volume of salt water tank | 40엘 |

| Compressed air pressure | 1.00±0.01kgf/cm2 |

| Volume of spray | 1.0-2.0ml/80cm2.h |

| Laboratory relative humidity | 85% ~ 위에 |

| Heat speed | 1:Test room,RT---→35℃ About 35minutes 2:Pressure barrel,RT---→47℃ About 15minutes |

LS-207-1 ASTM B117 ISO 9227 염수 분무 시험기(200유형)

캐릭터

| 1. | Imported gray P.V.C board, special treatment resistant to corrosion.V – shaped frame and stainless steel tube Angle, make sure the test object into 30 degrees Angle, four wheels glide, can push to go. |

| 2. | Fine workmanship, beautiful appearance, high transparency, pneumatic open cover. |

| 3. | Automatic/manual water filling system is adopted, with the function of automatic/manual water filling when water level is insufficient.The experiment will not be interrupted to meet the diversified environmental requirements of the guests.(automatic water rehydration only needs to be connected to the water pipe.) |

| 4. | 대통 주둥이: the spray tower is equipped with a cone disperser, which can guide fog, regulate the amount of fog, and even fog falling. |

| 5. | Use high-precision multi-function timer and the test time can be set to multi-function. With the power failure memory function, continue to work after the power failure, until the required time is completed, and avoid redoing the experiment after the power failure. |

| 6. | In the salt spray test, direct steam heating is adopted, the heating speed is fast, the temperature distribution is uniform, and the standby time is shortened. |

| 7. | Two-key automatic operation.With full trouble warning system.When the fault occurs, the light can be turned on and the buzzer will alarm. |

| 8. | Two internal fog collecting tubes are used.It is less likely to be damaged than the traditional outer-type. |

| 9. | With overload short-circuit protection.To prevent the damage of the instrument and its internal electronic control parts. |

| 10. | The inner and outer box is connected with the seal groove and sealed with water。 |

| 11. | The imported temperature controller USES digital display,PID control,error±0.1℃。 |

| 12. | 온도 범위:1:Test room temperature:35℃--Pressure barrel temperature:50℃(can set) 2:Test room temperature:47℃--Pressure barrel temperature:63℃(can set) |

| 13. | The refill bottle is made of recessed water level window, which is easy to clean. |

| 14. | Heat speed:1:Test room,RT---→35℃ About 35minutes 2:Pressure barrel,RT---→47℃ About 15minutes |

| 15. | Temperature accuracy:± 1 ℃ |

| 16 | International standard:RELATEU STANDARDS CNS 3627、3885、4159、7669、8866; JIS D-0201、H-8502、H-8610、K-5400、Z-2371、ISO3768、3769、3770; ASTM B-117、ASTM B-268 B-268、GB-T2423、GJB150。 |