Abstract.

In this paper, the technical characteristics, selection method and operation method of experimental film coating machine are discussed in depth, so as to provide comprehensive understanding and guidance for scientific researchers and engineers. Experimental film coating machine plays a vital role in various fields of research, and its accurate film coating process is of great significance for material research and electronic device preparation. This article will be divided into three main parts, firstly introduce the technical characteristics and application field of the experimental coating machine, then discuss the selection method in detail, and finally discuss the operation method and precautions.

Experimental coating machine technology research: selection, operation and application guide

First, the technical characteristics and application fields of the experimental coating machine

1.1 Technical Features

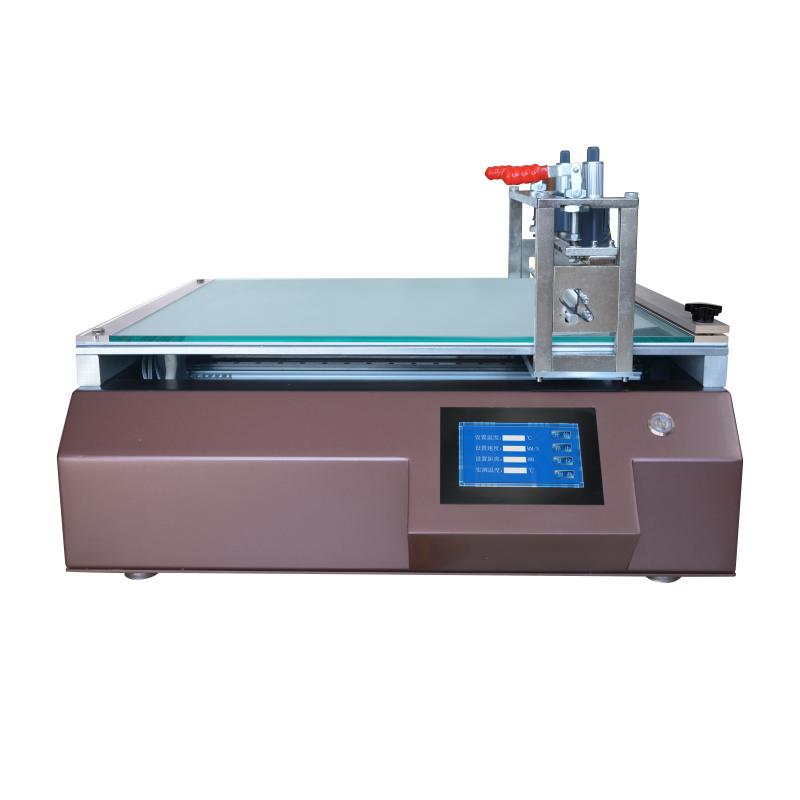

The experimental film coating machine is a device used to uniformly coat a film on the surface of a material, and its main technical features include:

1.1.1 Precision control system: The experimental coating machine is equipped with an advanced coating control system, which can achieve accurate control of key parameters such as coating thickness and uniformity.

1.1.2 Multifunctional coating heads: Coating machines are usually equipped with different types of coating heads, which can be applied to different coating materials and application scenarios.

1.1.3 High vacuum environment: For some special materials, the experimental coating machine can be coated in a high vacuum environment to ensure the purity and stability of the material.

1.1.4 Automatic control: Modern experimental coating machine usually adopts automatic control system, which can realize automatic coating process and improve experimental efficiency.

Experimental coating machine technology research: selection, operation and application guide

1.2 Application Fields

Experimental coating machine is widely used in various fields, mainly including but not limited to the following aspects:

1.2.1 Material research: New materials often need to be coated in the laboratory to change their surface properties, and the experimental coating machine can provide a highly controllable coating process to meet the needs of scientific research.

1.2.2 Optical coating: In the preparation of optical devices, the experimental coating machine can be applied to the preparation of optical coatings to improve the performance and stability of devices.

1.2.3 Preparation of electronic devices: For the preparation of semiconductors, optoelectronic devices, etc., the experimental film coating machine can achieve accurate coating of the film and improve the performance of the device.

1.2.4 Film research: For the research of film materials, the experimental film coating machine can provide a reliable experimental platform for film growth and characterization.

Technical exploration of experimental coating machine: Selection, operation and application guide Figure 2

Experimental coating machine technology research: selection, operation and application guide

Second, the selection method of experimental coating machine

2.1 Selection of coating materials

The selection of experimental coating machine must first consider the type of coating material, and different coating materials require different types of coating heads and coating systems. Common coating materials include metals, semiconductors, ceramics, etc., and choosing the right coating machine is crucial to obtaining a high-quality coating.

2.2 Selection according to coating thickness and uniformity requirements

Different application scenarios have different requirements for coating thickness and uniformity, so the control ability of the experimental coating machine for these parameters needs to be considered in the selection. Some high-end coating machines are equipped with advanced control systems that can achieve nanoscale coating thickness control and uniformity control.

2.3 Consider the experimental environment and scale

The experimental environment and experimental scale in the laboratory are also important considerations for selection. Some experimental coating machines need to operate in a high vacuum environment, while others can be coated under normal temperature and pressure conditions. In addition, some large-scale experiments need to have a high throughput coating capacity, and small-scale experiments can choose a simpler experimental coating machine.

Experimental coating machine technology research: selection, operation and application guide

2.4 Consider budget and maintenance costs

The price and maintenance cost of the experimental coating machine vary greatly, so the budget of the laboratory needs to be considered in the selection. At the same time, it is necessary to evaluate the maintenance difficulty and maintenance cost of the equipment to ensure the long-term stable operation of the equipment.

Third, the operation method and precautions of the experimental coating machine

3.1 Operation Method

The operation method of the experimental coating machine generally includes the following steps:

3.1.1 Equipment preparation: Ensure that all parts of the coating machine are in normal working condition, including coating head, vacuum system, control system, etc.

3.1.2 Sample preparation: Place the sample to be coated on the sample table and ensure that the surface of the sample is clean and free of impurities.

Experimental coating machine technology research: selection, operation and application guide

3.1.3 Parameter setting: According to the coating material and requirements, set the parameters of the coating machine, including coating speed, vacuum degree, working temperature of the coating head, etc.

3.1.4 Coating process: Start the coating machine and start the coating process. The coating thickness and uniformity can be monitored in real time during the coating process and adjusted as needed.

3.1.5 Coating completion: After coating completion, stop the work of the coating machine and remove the sample for subsequent treatment or analysis.

3.2 Precautions

During the operation of the experimental coating machine, the following matters need to be noted:

3.2.1 Safe operation: The operator should strictly abide by the safety regulations of the film coating machine to ensure safe operation in a high vacuum environment and avoid accidents.

3.2.2 Selection of coating materials: Select appropriate coating materials according to the experimental requirements to ensure that the quality and performance of the coating meet the experimental requirements.

3.2.3 Parameter adjustment: It is necessary to monitor the thickness and uniformity of the coating at any time during the coating process, and adjust the parameters according to real-time data to ensure the coating quality.

3.2.4 Equipment maintenance: Maintain the coating machine regularly, clean the coating head, check the vacuum system, etc., to ensure the long-term stable operation of the equipment.

Experimental coating machine technology research: selection, operation and application guide

conclusion

As a key experimental equipment, the experimental coating machine plays an important role in the fields of material research and device preparation. The selection of coating materials, thickness and uniformity requirements, experimental environment and scale, budget and other factors need to be considered to ensure the selection of appropriate equipment. During operation, pay attention to safe operation and parameter adjustment during the coating process, and periodically maintain the device to ensure long-term stable operation of the device. Through in-depth understanding of the technical characteristics and operation methods of the experimental coating machine, researchers and engineers can better use this advanced equipment to carry out coating experiments and promote the development of scientific research and technological innovation.