- Descripción

- Investigación

Plasma surface treatment machine for Activation decontamination improves hydrophilicity,Plasma cleaning machine

Caracteristicas de producto

1. Change the surface properties of materials to improve adhesion

2 Can be connected with the production line to realize automatic production

3 Low temperature plasma cold arc discharge technology

4. Multiple types of nozzles can be selected for a wide range of use

5. Improve production quality, environmental protection and energy saving

6. Good security, multifunctional safety protection

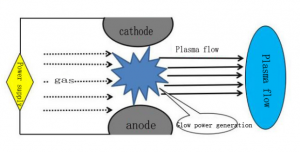

Plasma cleaning principle: plasma cleaning technology uses the characteristics of low temperature plasma to contact and react with the surface of the material, so that the surface of the material being treated can be cleaned chemically and physically, improve the surface moistness, implant new chemical functional groups and surface etching

Plasma surface treatment machine for Activation decontamination improves hydrophilicity,Plasma cleaning machine

Plasma surface treatment machine for Activation decontamination improves hydrophilicity,Plasma cleaning machine

Industria de aplicaciones

Photoelectric and electronic industry applications

1. Todo tipo de limpieza de superficies de vidrio., improve the hydrophilicity of glass surface, optimize the process of glass coating printing, bonding and spraying;

2. Limpieza de contactos de placas de circuito impreso flexibles y no flexibles, lámpara fluorescente LED “contact cleaning and improve the surface glue fastness;

3 Limpieza de PCB de componentes electrónicos, Limpieza de superficies de circuitos integrados, activation enhancement binding and other

4.LCD terminals before bonding plasma cleaning;

Aplicación en la industria automotriz

1. Tira de sellado de EPDM para automóviles, tratamiento previo de flocado y revestimiento previo en lugar de utilizar revestimiento base;

2. Base de lámpara para coche, ranura, pastilla de freno, unión de parachoques, Pretratamiento con plasma antes de la pulverización.;

3 Pretratamiento de neumáticos antipinchazos de automóviles antes del pegado.:

4. New energy automobile battery electrode welding, activación de la superficie del recubrimiento, limpieza, etc

Aplicación en la industria del plástico

1.PÁGINAS, CLORURO DE POLIVINILO, MASCOTA, ordenador personal, EDUCACIÓN FÍSICA, PTFE and other plastic materials spraying, impresión, galvanoplastia, bonding and flocking pre-treatment;

2. Todo tipo de plastico, silicona, caucho, Pulverización de metales y otros materiales., impresión, plating bonding before surface modification, eliminación de contaminantes superficiales;

3. Pretreatment before printing and painting of mobile phones, ordenadores, toys and other plastic shells to improve surface adhesion;

4. Preprocesamiento de botellas cosméticas de plástico antes de imprimir., improve surface adhesion can prevent word falling off and improve product quality;

Aplicación en la industria del embalaje

1. Professional improvement of coated paper, papel de glaseado, pulido, tarjeta de oro y plata, papel chapado en aluminio, UV, OPP, PÁGINAS, Cajas de PET y otros colores., caja de color superficie pegar caja solidez;

2. Plasma pretreatment before welding of milk powder cans and beverage cans;

Aplicaciones de la industria de impresión y codificación

1. Pretratamiento con plasma antes de la tampografía, Serigrafía y codificación por chorro en la superficie del plástico., metal, glass and other composite materials to

improve the adhesion of material surface to ink;

2.EDUCACIÓN FÍSICA, PTFE, silicone rubber wire and cable coding before processing 3.PVC, MASCOTA, ABS smart card coding before pretreatment

Aplicación en la industria de electrodomésticos

1. Plasma activation before surface coating, spraying and bonding of daily necessities and household appliances can improve surface adhesion and bonding force.

2. Printing before processing, can make the printing more firm not to fall off

Plasma surface treatment machine for Activation decontamination improves hydrophilicity,Plasma cleaning machine

Customer case