- Descripción

- Investigación

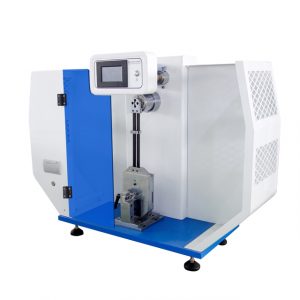

LS-137 6 work station HDT Vicat Tester

1.Introducción del producto:

Thermal Deformation Vicat, Softening Point Temperature Tester is using PLC programmable controller temperature control using computer display operation.The product is simple to operate, conveniente de usar, stable in performance, high in precision, and can monitor the test temperature and deformation amount in real time during the test.At the end of the test, the system automatically stops heating and can print test reports and test curves.This series of machines are necessary instruments for self-inspection by quality inspection units, colleges and universities and enterprises.

2、Carácter del producto:

Have sample frame lifting function, can at the end of the trial begins or lifting or lowering the specimen holder, this machine is mainly used for non-metallic materials such as plastic, caucho, nylon, electrical insulating materials of the thermal deformation temperature and vicat softening point temperature measurement.

LS-137 6 work station HDT Vicat Tester

3.Estándar de prueba:

- GB/T1633《Determination of vika softening temperature (VST) of thermoplastic》

- GB/T1634《Determination of plastic load deformation temperature – part 1: general test method》

- GB/T8802《Determination of softening temperature of plastic pipe fittings》

- IS075-2013《Measurement of plastic load deformation temperature》

- ASTM D 648《Test method for temperature of plastic thermal deformation》

- ASTM D 1525《Plastic Vicat softening test method.

4.Ventajas del producto

- Ø Intelligent PID regulation, accurate heating rate, accurate temperature control and no difference

- Ø4 Group independent temperature display 4 groups of imported PT100 temperature sensors, accuracy ±0.5% class.

- Ø Can perform thermal deformation test of a variety of standard splines

- Ø Can perform vicar softening point test of a variety of standard splines

- Ø Can simultaneously perform thermal deformation and Vicar softening point test

- Ø Calculates the required load automatically based on the test standard and spline size

- Ø Selects two heating rates, free switch and simple operation

- Ø Whole computer system operates to observe the temperature-deformation curve in real time, and the test is completed automatically.

- Ø Test condition and test standard are built in and can be retrieved at any time without the need to calculate the deflection and deformation.

- Ø Adopts imported micrometer (Taiwan EEE), which is reliable and stable. The precision is higher than the resistance gauge.

- Ø Hot deformation indenter and vicar indenter use high strength and light weight imported alloy material, and the high-temperature expansion coefficient is less than the standard requirement.

- Ø Electric lifting sample stand. Six or more groups can be lifted simultaneously to facilitate the change of test samples under high temperature and reduce manual operation

- Ø Test completes to automatically store data to facilitate access later and to export the test report at any time

- Ø Stirring motor adopts imported speed regulating motor, no vibration, reasonable design, the temperature uniformity of internal silicone oil can reach ±1℃

- ØTests completes or exceeds the temperature upper limit and switches off the temperature control

- Ø Has both software overtemperature protection and external mechanical overtemperature protection to facilitate testing

- Ø Diversified report setup, complete report printing function

LS-137 6 work station HDT Vicat Tester

- 5.Especificación técnica:

- Rango de control de temperatura:Normal temp—300℃

- Heating speed:(120±10)℃/h (12±1)℃/6min

(50±5)℃/h (5± 0,5)℃/6min

- Temperature indication error:1℃

- Precisión del control de temperatura:±0,5 ℃

- Maximum deformation indication error:±0.001mm

- Deformation measurement range:0—2mm

- Number of sample frames:3pcs

- Load rod and tray weight:68gramo

- Test span range: 64 or 100mm (according to the standard)

- Heating medium: methyl silicone oil or transformer oil

- Cooling method: mas que 150 natural cooling, 150 under water or natural cooling

- Heating power:4kw

5.rapidez del color

- Computadora (configuración:industrial computer)1piezas

- Printer 1pcs(HP,Opcional)

- Electric control box1pcs

- Host machine 1pcs

- Sampleshelf frames 6pcs

- Hot deformation pressure heads6pcs

- Vicat needles6pcs

8.sets of weights (including weights in boxes) (attached table) 6colocar

- Multi-purpose power socket 1pcs

6.Attached form :(accept non-standard customization)

| Peso | Qty Pcs | Peso | Qty Pcs |

| 1000gramo | 12 | 932 | 3 |

| 500gramo | 3 | 200gramo | 6 |

| 100gramo | 3 | 50gramo | 3 |

| 20gramo | 6 | 10gramo | 6 |

| 5gramo | 3 | 2gramo | 3 |

| 1gramo | 3 |

Software