- 描述

- 查询

plasma surface treatment machine,Product adhesion improved,Surface treatment before bonding

Activated surface

Improve the hydrophilicity of the product

提高产品表面附着力

印刷粘合前处理

环保技术, 低温等离子体, 增加印刷, 配发, 涂层及其他粘合效果

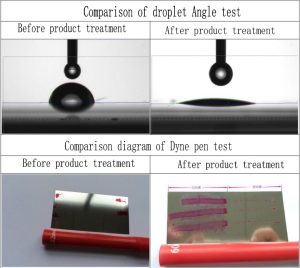

Dyne pen test: The Dyne pen is perpendicular to the surface of the material to be tested, and a straight line is drawn uniformly on the surface. If it is straight and does not shrink within 2-3 秒, it indicates that the surface tension of the material has reached the tension value of the test pen. If the tip of the pen is broken and condensed into small droplets, it indicates that the test pen tension value has not been reached.

plasma surface treatment machine,Product adhesion improved,Surface treatment before bonding

航空工业

等离子清洗应用

随着航空业的发展, manufacturers will be looking for products with longer life, more reliable quality and lower cost. Previously, aircraft masks and strips were made of aluminum alloy, 但现在, 这些部件主要由碳纤维增强塑料制成. 等离子体在这方面发挥着重要作用. Carbon fiber reinforced plastic surface stability is better, so that the bonding and spraying process presented a more perfect state

金属行业

(Whether it’s the metal accessories we wear or the metal tables and chairs we use in our homes, they may all have plasma treated surfaces. 如今, people are becoming more and more sophisticated in product design. 厂家为了满足消费者的需求就会生产出各种美观耐用的金属制品来吸引市场, 可以说,材料的等离子表面处理已经渗透到我们的生活中, in the past 30 年, 低温等离子体广泛用于改变金属材料表面的力学性能, 金属的等离子表面处理是 :1. 离子束渗氮可提高钢铁合金的摩擦和耐腐蚀性能. 2. When ions are injected into metal surface, metal solid solution and sediment can be formed, 从而提高金属材料的硬度和耐磨性

医疗行业

医用材料是指与生物组织接触而形成功能的无生命材料. 它们是很好的医疗辅助材料, 包括高分子材料, 金属, 陶瓷, 玻璃或各种材料的复合材料, 等等, 广泛应用于人造器官, 手术修复, 牙科材料, 包层材料, 骨科器械和药品. 功能和机械性能, 这些材料非常好, 但良好的生物相容性也相当关键, 采用等离子表面改性方法可以使它们具有良好的相容性, 等离子仅在表面进行一薄层处理, 不改变材料的性能, 和杀菌效果. 因此等离子表面处理在医用材料上的应用越来越广泛.

家电行业

表面涂层, 日用品、家用电器的喷涂、粘接工艺. 等离子预处理可提高产品的结合和涂层质量

塑料行业

塑料, 橡胶, 金属等粘接前的预处理, 提高表面附着力, 手机, 电脑, 玩具等塑料外壳喷涂预处理, 提高表面附着力

包装行业

在印刷包装领域的应用, 或许在等离子表面处理之前,公众并不多知道什么, 当使用摆杆 Sunny 测试仪测量涂层厚度时, 我们很早就开始使用电晕放电, 火焰处理表面改性方法, 那是, 离子体中最常见的放电形式 – 介质阻挡放电 (DBD) 但现在低温等离子处理机已经广泛应用于包装行业, 改变包装表面的印刷适性和复合表面的附着力, UV等离子处理功能, 涂层, 玻璃窗, 聚合物及其他材料表面处理; 专业改善铜版纸, 釉面纸抛光, 金卡和银卡, 镀铝纸, 紫外线, OPP, 聚丙烯, PET等彩盒, 彩盒表面贴盒牢度; 消除各类包装盒开启问题. 提高工作效率, 减少磨削污染, 消除糊盒机纸粉污染, 节省耗材, 节省胶水成本

光电玻璃及电子行业应用

各类玻璃表面清洗, 提高玻璃表面亲水性, optimize the plating, 印刷, 粘合和喷涂技术;

@ Flexible and non-flexible printed circuit board contact cleaning, LED日光灯 “接触” 清洁并提高表面粘合牢固度;

精密玻璃

@ Electronic components, PCB cleaning, IC表面清洗, 激活增强结合, 等等; @LCD LCD screen terminal surface before plasma cleaning;

电子行业

Electronic components processing of plasma pretreatment, PCB cleaning, electrostatic removal, LED support, IC surface cleaning and bonding

汽车行业

三元乙丙胶条喷涂润滑涂层或植绒胶预处理工艺; 等离子表面预处理技术用于汽车大灯粘接, 刹车片雨刮器, 兜帽, 仪表和保险杠