- 描述

- 查询

LS-101-3 Electronic Loading Melt Flow Index Tester

说明:

This is for high-precision melt flow rate instrument tester, used for testing all kinds of plastic, resin in the state of viscous flow through a certain temperature and load, every 10 min module and melt flow rate through the standard port MFR/MVR value, it is suitable for high temperature of polycarbonate, aromatic sulfone, fluorine plastics, nylon engineering plastics, can also be applied to polyethylene (体育), 聚苯乙烯 (附言), 聚丙烯 (聚丙烯), ABS resin, polyformaldehyde (聚甲醛), polycarbonate (个人电脑) resin with lower melting temperature, such as plastic test, widely used in plastic production, plastic products, petrochemical industry and related colleges and universities.

标准:

GB/T3682-2018、ISO1133-2011, ASTM D1238-13

LS-101-3 Electronic Loading Melt Flow Index Tester

产品特征:

Ø 1.More paragraphs (3) temperature control method, three groups of platinum resistance sensor, the three heating jacket separate temperature control, high accuracy intelligent PID control, ramp rate the heating speed is adjustable

Ø 2.Resolution temperature was 0.1 ℃, the temperature fluctuation of not more than 0.5 ℃ within 24 小时, the displacement sensor resolution is 0.001 毫米.

Temperature and temperature protection device

Ø 3.Hand automatic cutting material, can be arbitrary set blanking time (0 〜 999), blanking times (0 〜 999)

Ø 4.Test can choose quality standard, or volume method, two test methods or simultaneously, and can calculate flow rate ratio.Both methods start testing when the piston rod moves to a certain location.

Ø 5.Can be set up in 240 秒 (GB3682 regulations) material preheat second countdown, after the end of the countdown, farmar automatically loaded, loaded to interval start automatic cutting, can also set the American standard (哮喘) preheating time, 等等.

Ø 6.Built-in many plastic material melt index test conditions, convenient customer used to be obtained at any time, reduce the tedious work, and storing the last test conditions and results

The internal microtyping machine is convenient for printing and testing data

Ø 7.High precision touch screen controller, 7 英寸触摸屏, can be stored and print test conditions and data recently, test print menu Settings include test time (the default), the material name, test conditions (温度, weight weight, blanking intervals), test results data.

Ø 8.Reserved RS232 interface or USB interface to connect computers, can through the computer control instrument operation and to save test data transmission to the computer,

Ø 9.Can manually loading weight or by stepping motor drives the ball screw rotation in order to achieve the purpose of automatic control at the top of the load weight increase or decrease

测试方法:MFR +MVR Methods

显示模式:英文彩色触摸屏显示

LS-101-3 Electronic Loading Melt Flow Index Tester

规范

| 模型 | LS-101-3 |

| 枪管参数 | Inner hole 9.550±0.005mm length 163mm |

| Pistons head parameters | 活塞头: 9.474±0.005mm |

| Piston rod diameter | 8.94毫米 |

| Mold length | 8.000±0.025mm |

| Mold nominal inner diameter | 2.0955±0.0051mm

|

| Half die length | 4.000±0.025mm |

| Half die nominal inner diameter | 1.050±0.005mm |

| 温度参数 | 带智能温控仪表, 具有四对显着温度设定控制, PID参数可自动设定, 精度高达± 0.1 摄氏度 |

| 强电磁辐射源 | Room Temperature~500degree centigrade |

| 强电磁辐射源 | ±0.2℃ |

| 温度均匀性 | ±1℃ |

| 温度显示分辨率 | 0.1℃ |

| 显示分辨率 | 0.1℃ |

| 最大消耗 | < 600w ^ |

| 时间显示分辨率 | 0.1s |

| 权重参数如下: | |

| 重量精度 | ±0.5% |

| 基本配置

| 一个 0.325 公斤 |

| 1.2公斤 | |

| 2.16公斤 | |

| 3.8公斤 | |

| 5公斤 | |

| F 10公斤 | |

| 克 12.5 公斤 | |

| 高 21.6 公斤 | |

| 位置检测 | |

| 上下环距 | 30毫米 |

| 控制精度 | ± 0.1mm |

| 测试流控制 | |

| 切割材料的次数 | 0~10次 |

| 材料切割间隔 | 0~999s(设置参考表 2) |

| 控制流量达到设定温度无波动 | |

| 桶温时间 | 15 分钟. |

| 安装材料 | 1 分钟. |

| 材料样品温度恢复时间 | 4 分钟. |

| 当粘合剂凝固 | 1分钟 |

| 输出方式 | 微自动打印输出 |

| 切割材料方法 | 手自动切一体 |

| 测试负载 | 八组砝码 |

| 功率 | AC220V±10% 50/60HZ |

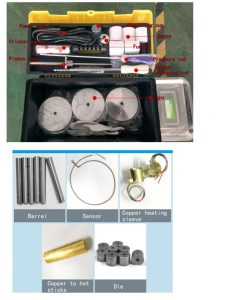

配件清单

| 没有 | 名称 | 数量 | 评论 |

| 1 | 重量 | 1 放 | 0.325㎏、0.875㎏、1.835㎏、2.5㎏、2.915㎏、3.475㎏、4.615公斤、5.0公斤 |

| 2 | 重量托盘 | 1件 | 层内 1 加载 |

| 3 | 装料斗 | 1件 | |

| 4 | 口模清洁棒 | 1件 | |

| 5 | 充电棒 | 1件 | |

| 6 | 气缸清洁棒 | 1件 | |

| 7 | 活塞杆 | 1件 | |

| 8 | 口模 | 1件 | |

| 9 | 纱布 | 2卷 | |

| 10 | 打印纸 | 2 卷 |

标准试验力(8级)

1 等级:0.325 kg=(活塞杆+配重托盘+隔热罩+无 1 重量)

=3.187N

2 等级:1.200 公斤=(0.325+2号 0.875 强电磁辐射源)=11.77 牛

3 等级:2.160 公斤=(0.325+3号 1.835 重量)=21.18 牛

4 等级:3.800 公斤=(0.325+No4 3.475重量)=37.26 牛

5 等级:5.000 公斤=(0.325+No.5 4.675重量)=49.03 N

6 等级:10.000 公斤=(0.325+No.5 4.675重量+No.6 5.000重量)=98.07 N

7 等级:12.000 公斤=(0.325+No.5 4.675weight+No.6 5.000+No.7 2.500weight)=122.58 牛

8 等级:21.600 公斤=(0.325+No.2 0.875重量+No3. 1.835+4号

3.475+No.5 4.675+No.6 5.000+No.7 2.500+No.8 2.915重量)=211.82 牛

List of components

| 没有 | 名称 | 单元 | 数量 | 评论 |

| 1 | Relay | 放 | 3 | Taiwan YangMING |

| 2 | Temperature Sensor | 件 | 2 | UK RS PT100 |

| 3 | 开关;电源开关 | 件 | 1 | Zheniang hongbo |

| 4 | Heating jacket | 件 | 2 | High temperature pure copper heating sleeve |

| 5 | 控制器 (including touch screen) | 件 | 1 | Self-developed, intelligent multi-point temperature control system (including 7-inch touch screen) |

| 6 | Lifting motor | 件 | 1 | Taiwan puloviac AC motor |

| 7 | Cutting machine | 件 | 1 | Taiwan imports pulovid |

| 8 | Transformer | 件 | 1 | Guangzhou baiyun |

| 9 | Encoder | 件 | 1 | Japan’s original omron |

| 10 | Opening mould | 件 | 1 | Tungsten steel |

| 11 | Cylinder | 件 | 1 | The treatment of nitrification and corrosion resistance |

| 12 | 打印机 | 件 | 1 | Beijing weihuang |

图表 1

| 熔体流速 (克/10分钟) | 装料桶样品质量 (G) | 挤出切断间隔时间 (s) |

| 0.1-0.5 | 3-5 | 240 |

| >0.5-1 | 4-6 | 120 |

| >1-3.5 | 4-6 | 60 |

| >3.5-10 | 6-8 | 30 |

| >10 | 6-8 | 5-15 |

| 1. 如果这个实验值小于 0.1 G / 10 最小或大于 100 G / 10 分钟, 建议你熔体流动速率 2. 当材料密度大于 1.0 G / 10 分钟, 可能需要增加样本量. | ||

图表 2

| 一次性解决超薄膜镀膜问题 | 测试温度θ,℃ | 跟我一起标准负荷,公斤 |

| 附言 | 200 | 5.00 |

| 体育 | 190 | 2.16 |

| 体育 | 190 | 0.325 |

| 体育 | 190 | 21.60 |

| 体育 | 190 | 5.00 |

| 聚丙烯 | 230 | 2.16 |

| ABS | 230 | 10.00 |

| PS-1 | 200 | 5.00 |

| 电子/空调 | 150 | 2.16 |

| 电子/空调 | 190 | 2.16 |

| 电子/空调 | 125 | 0.325 |

| SAN | 220 | 10.00 |

| 作为一个、ACS、AEC | 220 | 10.00 |

| 个人电脑 | 300 | 1.2 |

| 聚甲基丙烯酸甲酯 | 230 | 3.8 |

| 铅 | 190 | 2.16 |

| 铅 | 190 | 10.00 |

| 聚甲醛 | 190 | 2.16 |

| MABS | 220 | 10.00 |

软件