- Описание

- Запрос

- 1. Scope of application:

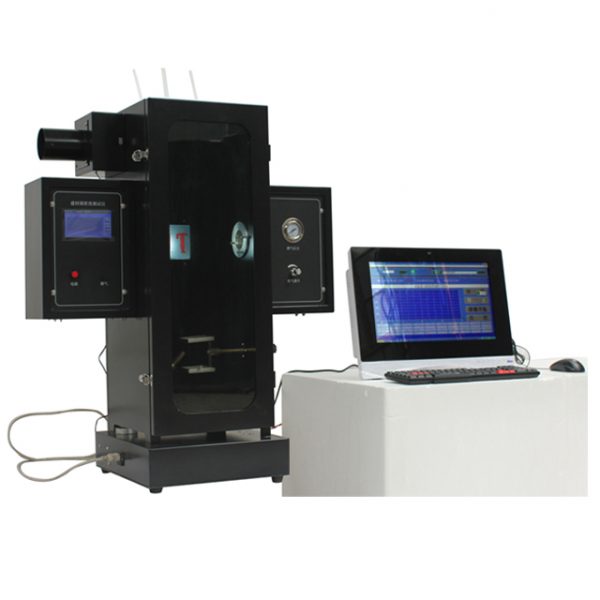

Touch-screen computer dual control smoke density tester for building materials was developed according to the technical conditions stipulated in GB/ t8627-2007 “test methods for smoke density of burning or decomposition of building materials”, which is applicable to the measurement of static smoke production from burning of building materials, products and other materials.

- Особенности продукта

- Dual control mode, can control the operation on the touch screen, can also be controlled on the computer, the operation mode can be arbitrarily switched!

- A device can operate several computers at the same time, several computers can be online at the same time, and LAN sharing can be realized!

- The main and auxiliary burners can rotate automatically and locate accurately.

- Independently developed the control program, which can meet all kinds of operations, records, real-time curves and results calculation in the test.

- Relevant technical parameters

- For the maximum smoke density (MSD) and smoke density grade (SDR) of the specimen: 0-100% continuously measurable and automatically calculated;

- Calibration error with standard filter shall not be more than 3%;Each device is equipped with three standard filters, which are representative of the data of light source calibration

- Working pressure of Bunsen burner (210 + 5) кПа;

- The Bunsen burner applied flame to the sample for 4min;

- Burning lamp: in the Bunsen burner and a length of 260 мм, the nozzle diameter of 0.13 мм, with smoke box into a 45 ° Angle;

- Photoelectric system: the light source is a bulb with 15W power and 6V working voltage;

- Exhaust air system: this machine is equipped with powerful exhaust fan, which can discharge exhaust gas out of the outdoor after the test;

- Smoke density measurement range: 0~100%;

- Smoke density measurement accuracy: ± 3%;

- Приемник: silicon photocell, light transmittance 0% is no light, light transmittance 100% is no shade completely through;

- Working pressure of main burner: 276кПа (регулируемый);

- Automatic timing, автоматическое зажигание, automatic smoke extraction;Optical flux can be divided into stages for linear correction test dataA more accurate;

- Touch the screen:

- Размер: 5 “effective display size 11cm long and 6.28cm wide;

- разрешение: 800*480

- Интерфейс связи RS232, 3.3v КМОП или ТТЛ, режим последовательного порта

- Вместимость склада :1грамм

- Чисто аппаратный дисплей привода FPGA, “Система электрических измерений и контроля” время запуска, мощность может работать

- Принята архитектура M3+FPGA. M3 отвечает за анализ инструкций, и FPGA фокусируется на TFT-дисплее

- Главный контроллер оснащен процессором с низким энергопотреблением и автоматически переходит в энергосберегающий режим.

- Источник газа: 95% propane gas, or gas of the same purity (customer provided);

- Длина * Новую батарею можно использовать непрерывно более * Новую батарею можно использовать непрерывно более 740 *500* Новую батарею можно использовать непрерывно более 900 (мм)

- Условия труда:

- Новую батарею можно использовать непрерывно более: 0 Введение 40 ℃;

- Относительная влажность: меньше, чем 85%

- Напряжение и мощность источника питания: 220V + / – 10%, 50Гц, 100W;

- Gas pressure: 0-0.3МПа (регулируемый);

- Environment and test requirements: avoid direct irradiation or reflection of strong light on the instrument during operation;After the test for 90min, the gas source should be turned off to cool the instrument for 15min.

- Ambient air flow: there is no forced air flow phenomenon when working;

- The instrument should be placed in the fume hood for testing;

- Структура инструмента:

Divided into smoke box and control two parts;

Smoke box: on the left and right sides of the smoke box panel, there are power switch, safety sign switch (back light switch), gas regulator, in addition to the control exhaust fan switch (fan switch).

Мы. Стандарт дизайна: GB/ t8627-2007 smoke density test method for combustion or decomposition of building materials

Стандарт: GB/T8627 ASTM D2843