- Descriere

- Anchetă

Plasma surface treatment machine for Activation decontamination improves hydrophilicity,Plasma cleaning machine

Product characteristics

1. Change the surface properties of materials to improve adhesion

2 Can be connected with the production line to realize automatic production

3 Low temperature plasma cold arc discharge technology

4. Multiple types of nozzles can be selected for a wide range of use

5. Improve production quality, environmental protection and energy saving

6. Good security, multifunctional safety protection

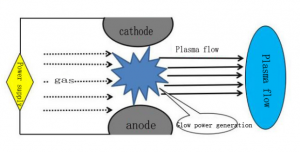

Plasma cleaning principle: plasma cleaning technology uses the characteristics of low temperature plasma to contact and react with the surface of the material, so that the surface of the material being treated can be cleaned chemically and physically, improve the surface moistness, implant new chemical functional groups and surface etching

Plasma surface treatment machine for Activation decontamination improves hydrophilicity,Plasma cleaning machine

Plasma surface treatment machine for Activation decontamination improves hydrophilicity,Plasma cleaning machine

Application industry

Photoelectric and electronic industry applications

1. Toate tipurile de curățare a suprafețelor de sticlă, improve the hydrophilicity of glass surface, optimize the process of glass coating printing, bonding and spraying;

2. Curățare flexibilă și neflexibilă a contactelor plăcii de circuit imprimat, Lampa fluorescenta cu LED “contact cleaning and improve the surface glue fastness;

3 Electronic components PCB cleaning, Curățarea suprafețelor IC, activation enhancement binding and other

4.LCD terminals before bonding plasma cleaning;

Aplicație în industria auto

1. Bandă de etanșare EPDM pentru automobile, flocare și pre-acoperire pretratare în loc de a utiliza acoperirea de bază;

2. Baza lămpii auto, canelură, plăcuță de frână, lipirea barei de protecție, pretratare cu plasmă înainte de pulverizare;

3 Pretratarea anvelopei auto anti-punctură înainte de lipire:

4. New energy automobile battery electrode welding, activarea suprafeței de acoperire, curatenie, etc.

Aplicație în industria materialelor plastice

1.PP, PVC, ANIMAL DE COMPANIE, PC, PE, PTFE and other plastic materials spraying, imprimare, galvanizare, bonding and flocking pre-treatment;

2. Toate tipurile de plastic, silicon, cauciuc, pulverizare de metal și alte materiale, imprimare, plating bonding before surface modification, eliminarea poluanților de suprafață;

3. Pretreatment before printing and painting of mobile phones, calculatoare, toys and other plastic shells to improve surface adhesion;

4. Preprocesare sticle cosmetice din plastic înainte de imprimare, improve surface adhesion can prevent word falling off and improve product quality;

Aplicație în industria ambalajelor

1. Professional improvement of coated paper, hârtie de glazură, lustruire, card de aur și argint, hârtie placată cu aluminiu, UV, OPP, PP, PET și alte cutii de culoare, cutie de culoare suprafață pasta de rezistență;

2. Plasma pretreatment before welding of milk powder cans and beverage cans;

Aplicații din industria de imprimare și codificare

1. Pretratare cu plasmă înainte de tampografie, serigrafie și codare cu jet pe suprafața plasticului, metal, glass and other composite materials to

improve the adhesion of material surface to ink;

2.PE, PTFE, silicone rubber wire and cable coding before processing 3.PVC, ANIMAL DE COMPANIE, ABS smart card coding before pretreatment

Aplicație în industria de electrocasnice

1. Plasma activation before surface coating, spraying and bonding of daily necessities and household appliances can improve surface adhesion and bonding force.

2. Printing before processing, can make the printing more firm not to fall off

Plasma surface treatment machine for Activation decontamination improves hydrophilicity,Plasma cleaning machine

Customer case