- Descriere

- Anchetă

Flexographic ink proofing machine

Use and Specification

Obiecte aplicabile: proofing monocrom (cum ar fi potrivirea culorilor, testarea, etc.)

Putere de intrare: 220V, 50/60HZ

Putere: 400Tensiune de intrare

Ink way: drip ink

Thickness of proofing material: 0.01-2mm (material îndoit)

Dimensiunea materialului de verificare: 170x220mm

Zona de imprimare: 117x138mm

Zona farfurii: 150x170mm

Grosimea farfuriei: USA Dupont 1.14mm thick resin plate back glue 0.38mm

Pressure of plate roller and anilox roller: adjustable by 土2mm, with scale to show pressure

Plate roller and embossing pressure: adjustable by 2mm, cu scară pentru a arăta presiunea

Viteza de imprimare reglabila: 0-120 m/min

Specification of ceramic roller:USA φ70x210mm

Lines number of ceramic roller: standard one 600LPI (70-1200 liniile pot fi personalizate) BCM:1.6-5.3

Applicable ink: flexographic waterborne, cerneală UV, litografie, relief ordinary or UV ink

Materiale de izolare adecvate: HG268 Contor de luciu unghi TRI, folie de plastic, non – woven fabric, şerveţel, gold and silver paper jam, etc.

External dimensions (length x width x height) : 450x800x240mm

Greutate netă: 110KG

UV curing device selection

The instrument can be coated, solid color, dot pattern proofing

Flexographic ink proofing machine

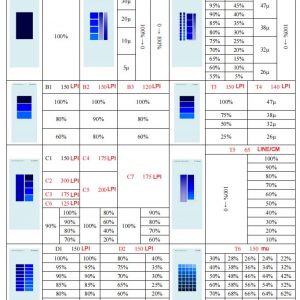

Specification of Ceramic anilox roller

1.BCM:2.0

2.Ink hole carving Angle:60°

3.ink cavity shape:Regular hexagon openings

4.Anilox roller wire Angle:45°

5.Number of anilox roller lines:600LPI

6.anilox roller concentric to beat:within 0.01mm

Flexographic ink proofing machine

Unique features of the instrument:

- After the ceramic roller rotates the ink evenly, the printing material and plate cylinder start up and rotate for one week to complete the proofing work. The ceramic roller and the printing material cylinder synchronize with the printing plate cylinder to ensure the quality of proofing.

- The four structures of scraper, ceramic roller, plate roller and printing material roller can adjust the pressure separately and adjust flexibly.

- Net roller, scraper disassembly and installation is simple and convenient

- Large cylinder structure is adopted to install printing materials, easy to install printing plate and clean printing plate.