- Omschrijving

- Onderzoek

Plasma surface treatment machine for Activation decontamination improves hydrophilicity,Plasma cleaning machine

Product characteristics

1. Change the surface properties of materials to improve adhesion

2 Can be connected with the production line to realize automatic production

3 Low temperature plasma cold arc discharge technology

4. Multiple types of nozzles can be selected for a wide range of use

5. Improve production quality, environmental protection and energy saving

6. Good security, multifunctional safety protection

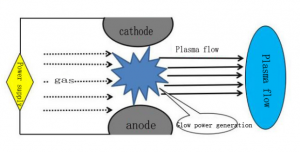

Plasma cleaning principle: plasma cleaning technology uses the characteristics of low temperature plasma to contact and react with the surface of the material, so that the surface of the material being treated can be cleaned chemically and physically, improve the surface moistness, implant new chemical functional groups and surface etching

Plasma surface treatment machine for Activation decontamination improves hydrophilicity,Plasma cleaning machine

Plasma surface treatment machine for Activation decontamination improves hydrophilicity,Plasma cleaning machine

Toepassingsindustrie

Photoelectric and electronic industry applications

1. Alle soorten glasoppervlaktereiniging, improve the hydrophilicity of glass surface, optimize the process of glass coating printing, bonding and spraying;

2. Flexibele en niet-flexibele contactreiniging van printplaten, LED-fluorescentielamp “contact cleaning and improve the surface glue fastness;

3 Electronic components PCB cleaning, IC-oppervlaktereiniging, activation enhancement binding and other

4.LCD terminals before bonding plasma cleaning;

Toepassing in de automobielindustrie

1. Automotive EPDM-afdichtstrip, massaal aanbrengen en voorbehandeling met voorcoating in plaats van het gebruik van een basiscoating;

2. Autolampvoet, groef, remblok, bumperverlijming, plasmavoorbehandeling vóór het spuiten;

3 Voorbehandeling van auto-antilekbanden vóór het lijmen:

4. New energy automobile battery electrode welding, activering van het coatingoppervlak, schoonmaak, enzovoort

Toepassing in de kunststofindustrie

1.PP, PVC, HUISDIER, Pc, AAN, PTFE and other plastic materials spraying, afdrukken, galvaniseren, bonding and flocking pre-treatment;

2. Alle soorten kunststof, siliconen, rubber, metaal en andere materialen spuiten, afdrukken, plating bonding before surface modification, verwijdering van oppervlakteverontreinigende stoffen;

3. Pretreatment before printing and painting of mobile phones, computers, toys and other plastic shells to improve surface adhesion;

4. Voorbewerking van plastic cosmetische flessen vóór het afdrukken, improve surface adhesion can prevent word falling off and improve product quality;

Toepassing in de verpakkingsindustrie

1. Professional improvement of coated paper, glazuurpapier, polijsten, gouden en zilveren kaart, aluminium geplateerd papier, UV, OPP, PP, PET- en andere kleurvakken, kleurdoos oppervlaktepasta doossnelheid;

2. Plasma pretreatment before welding of milk powder cans and beverage cans;

Toepassingen in de print- en codeerindustrie

1. Plasmavoorbehandeling vóór tampondruk, zeefdruk en jetcodering op het oppervlak van kunststof, metaal, glass and other composite materials to

improve the adhesion of material surface to ink;

2.AAN, PTFE, silicone rubber wire and cable coding before processing 3.PVC, HUISDIER, ABS smart card coding before pretreatment

Toepassing in de apparatenindustrie

1. Plasma activation before surface coating, spraying and bonding of daily necessities and household appliances can improve surface adhesion and bonding force.

2. Printing before processing, can make the printing more firm not to fall off

Plasma surface treatment machine for Activation decontamination improves hydrophilicity,Plasma cleaning machine

Customer case