- 説明

- 問い合わせ

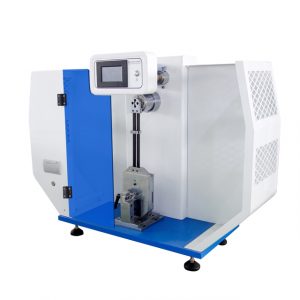

LS-101-3 Fully Automatic Melt Flow Index Tester

1.Product introduction:

This tester for high precision automatic melt flow rate instrument, used for testing all kinds of plastic, resin in the state of viscous flow through a certain temperature and load, every 10 min module and melt flow rate through the standard port MFR/MVR value, it is suitable for high temperature of polycarbonate, aromatic sulfone, fluorine plastics, nylon engineering plastics, can also be applied to polyethylene (PE), polystyrene (PS), polypropylene (PP), ABS resin, polyformaldehyde (POM), polycarbonate (PC) resin with lower melting temperature, such as plastic test, widely used in plastic production,Plastic products, petrochemical and other industries and related institutions, scientific research units and commodity inspection departments.

2.Test standard:

| GB/T3682-2018 | Measurement of melt flow rate and melt volume flow rate of thermoplastic plastics |

| ISO 1133:2011 | Determination of mass flow rate MFR and melt volume flow rate MVR of thermoplastic melt |

| ASTM D1238-13 | Standard test method for flow rate determination of thermoplastic melt by extruded plasticimeter |

LS-101-3 Fully Automatic Melt Flow Index Tester

3.Product advantage:

- Ø more paragraphs (2) temperature control method, two groups of platinum resistance sensor, two heating jacket separate temperature control, high accuracy intelligent PID control, ramp rate the heating speed is adjustable

- Ø resolution temperature was 0.1 ℃, the temperature uniformity of 0.2 ℃, the temperature fluctuation of not more than 0.5 ℃ within 24 時間, the displacement sensor resolution is 0.001 んん.

- Thermal protection device

- Ø hand automatic cutting material, can be arbitrary set blanking time (0 〜 999), blanking times (0 〜 999)

- Ø test can choose quality standard, or volume method, two test methods or simultaneously, and can melt density is calculated.Both methods are tested when the piston rod moves to a certain position.

- Ø stable internal temperature alarm prompts, and an increase of 240 秒 (GB3682 regulations) material preheat second countdown, after the end of the countdown, issued a prompt, can also set the American standard (喘息) preheating time, 等.

- Ø built-in many plastic material melt index test conditions, convenient customer used to be obtained at any time, reduce the tedious work, and storing the last test conditions and results

- Built – in mini printer for easy printing test data

- Ø high precision touch screen controller, 7 インチのタッチスクリーン, can be stored and print test conditions and data recently, test print menu Settings include test time (the default) system, operating personnel, material name, 試験方法, test conditions (NDJシリーズ粘度計, weight weight, blanking interval) データ, 試験結果, 試験結果, the artificial judgement OK or NG, NDJ-5S,

- Ø reserved RS232 interface or USB interface to connect computers, can through the computer control instrument operation and to save test data transmission to the computer,

- Ø need weight load, are installed in screen equipment to choose corresponding weight and loading that no user manual loading or bolt type selection, reduce the workload.Test completion self – rising.

Test Methods:MFR +MVR Methods

Display Mode:English color touch screen display

- Technical Speicification

| モデル | LS-101-3 |

| Barrel parameters | Inner hole 9.550±0.005mm length 163mm |

| Pistons head parameters | Piston head: 9.474±0.005mm |

| Piston rod diameter | 8.94んん |

| Mold length | 8.000±0.025mm |

| Mold nominal inner diameter | 2.0955±0.0051mm

|

| Half die length | 4.000±0.025mm |

| Half die nominal inner diameter | 1.050±0.005mm |

| Temperature parameter | With intelligent temperature control instrument, with four pairs of significant temperature setting control, PID parameters can be automatically set, precision up to ± 0.1 degree centigrade |

| サンプルバケット | Room Temperature~500degree centigrade |

| Temperature fluctuation | ±0.2 ℃ |

| Temperature uniformity | ±1℃ |

| Temperature display resolution | 0.1℃ |

| Display resolution | 0.1℃ |

| Maximum comsuption | < 600W |

| Time display resolution | 0.1NS |

| Weight parameters are as follows: | |

| Weight accuracy | ±0.5% |

| Basic configuration

| A 0.325kg |

| B 1.2kg | |

| C 2.16kg | |

| D 3.8kg | |

| E 5kg | |

| F 10kg | |

| G 12.5kg | |

| H 21.6kg | |

| Position detection | |

| Loop distance from up and down | 30んん |

| Control precision | ± 0.1mm |

| Test flow control | |

| Times of cutting the material | 0~10 times |

| Material cutting interval | 0~999s(set reference Table 2) |

| Control flow reaches the set temperature without volatility | |

| Barrel temperature time | 15 min. |

| Material be installed | 1 min. |

| Material sample temperature recovery time | 4 min. |

| When binder set | 1min |

| Output mode | Micro-automatic print output |

| Cut material methods | The hand automatic cut into one body |

| Test load | Eight sets of weights |

| 力 | AC220V±10% 50/60HZ |

LS-101-3 Fully Automatic Melt Flow Index Tester

5.Parts list

| 番号 | 名前 | 単位 | 数量 | 述べる |

| 1 | ホストマシン | セット | 1 | Include printer |

| 2 | 重量 | セットする | Total 8 レベル,0.325 kg,1.200 kg,2.160 kg,3.800 kg,5.000 kg,10.000 kg,12.000 kg,21.600 kg | (1# within level 1) |

| 3 | Weight tray | ピース | 1 | within level 1 |

| 4 | piston rod | ピース | 1 | within level 1 |

| 5 | mouth model | ピース | 1 | tungsten carbide |

| 6 | charging hopper | ピース | 1 | 温度と湿度 |

| 7 | loading rod | ピース | 1 | |

| 8 | Barrel cleaning lever | ピース | 1 | |

| 9 | Mouth die Cleaning rod | ピース | 1 | 温度と湿度 |

| 10 | Gauze | ピース | 2 | |

| 11 | Print paper | ピース | 2 | |

| 12 | その他 | Certificate of quality, specification, one feeding plate | ||

- ソフトウェア:

8.List of major accessories

| 番号 | 名前 | 単位 | 数量 | 述べる |

| 1 | relay | セットする | 3 | Taiwang yangming |

| 2 | 温度センサー | ピース | 2 | UK RS PT100 |

| 3 | Power switch | ピース | 1 | Zhejiang hongbo |

| 4 | Heating | ピース | 2 | High temperature resistant pure copper heating sleeve |

| 5 | 温度と湿度 (including touch screen) | ピース | 1 | Self-developed intelligent multi-point temperature control system (including 7-inch touch screen) |

| 6 | lifting motor | セットする | 1 | AC AC motor, plowway, Taiwan |

| 7 | cutting off motor

| セットする | 1 | Taiwan imports plowway direct current |

| 8 | transformer | セットする | 1 | Guangzhou baiyun |

| 9 | encoder | ピース | 1 | Original Japanese omron |

| 6 | Mouth die | ピース | 1 | tungsten steel |

| 7 | charging barrel | ピース | 1 | Nitriding treatment of harwood alloy, corrosion resistance |

| 8 | printer | ピース | 1 | Beijing weihuang |