- 説明

- 問い合わせ

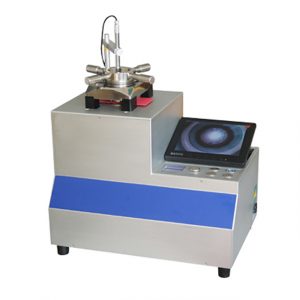

LS-309 Digital Cupping Tester

LS-309 Cupping Tester is applicable to evaluate crack resistance and detachment from the metal substrate of coated surface which is coated with paint, ワニス, NDJ-5S, after the coating layer is deformed gradually under standard condition. The sample panel(max. 1.25mm thick×70 mm width, coated min.0.03mm)is clamped by an upper wheel and manually cupped by a ф20mm hemispherical indenter onto a ф27mm die by a drive wheel. The depth to cause failure is indicated on a precise digital display. The results can be easily observed with an illuminated magnifier

◆ Compliance with ISO 1520,BS 3900 Part 4,DIN 53166,DIN 53233 等

◆ Automatic coordinate positioning system: tester can memorize the home position after being zeroed, also track the punch’s position automatically. したがって, the traditional error caused by return or shake can be avoided.

◆ Highly precise position sensor: the minimum division value of the depression depth can reach 0.01mm.

◆ Applicable for every kind of substrate, and the maximum pressure can reach 2500N.

◆ The coordinate position of the plug can be zeroed manually and can be memorized

◆ Come with 10X illuminated mangnifier, convenient to observe and judge test result.

◆ Hand twist operation: laborsaving and easy-handling.

LS-309 Digital Cupping Tester

Technical specification

■■ Diameter of punch: ф20mm

■■ Maximum dent thickness: 12んん

■■ Maximum depress power: 2,500N

■■ Resolution of dent: 0.01んん

■■ Counter: digital display, in 0.01mm increments

■■ Dimension of test pane:150mm×70mm ×0.03-1.25mm (Smooth, not deformed)

■■ 材料:polished steel panel

■■ 重量: 20Kg

■■ 寸法: 230×300×280mm (L×W×H)