- Descrizione

- Inchiesta

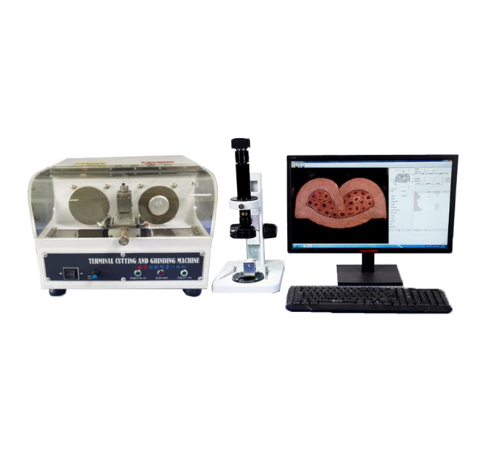

LS-VCG-100 Terminal Section Analyzer

introduzione

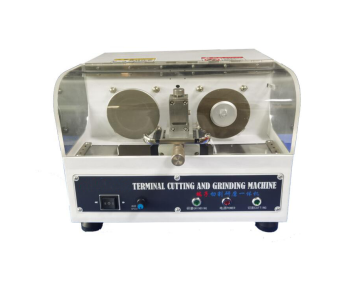

The terminal section analyzer adopts marble base, which makes the cutting and grinding machine work more stable. The motor adopts horizontal installation, which is convenient for cutting and grinding. The y-direction large range is adopted, and the cutting range is larger. Water spraying device can be added, which is suitable for cutting and grinding of large terminals of wire harness of more new energy vehicles. The cutting motor and the moving device of the terminal section analyzer are installed on the marble, and the accuracy of installation is guaranteed by meter making, so that the flatness of cutting and grinding is greatly improved.

LS-VCG-100 Terminal Section Analyzer

Caratteristiche:

- Use linear guide rail to ensure installation accuracy.

- The motor adopts horizontal installation to ensure small swing of rotation.

- Adopt grade 00 marble base to ensure alignment with cutting position.

- Optional XY mobile working platform with 360 degree rotating table, convenient terminal section sampling.

- Add dustproof system, easy to clean the machine.

- Fixture front, easy to install and adjust.

- Trigger switch to ensure personnel safety.

- Velcro sandpaper, quick replacement.

- Adopt 3 million pixel industrial camera, which can collect hd dynamic pictures.

- Built-in measurement standard analysis software, fast report export.

LS-VCG-100 Terminal Section Analyzer

- Main technical indicators

- Cutting module

Gamma: 0.01mm2 to 100.00mm2 (ø 0.10mm – ø 20.00mm)

Velocità: 2800 RPM

Cutting speed: manual adjustable

Cutting wheel: φ110 x 0.5 xφ20mm

- Polish the module

Velocità: 1400 RPM

Z fine tuning range: 0.0mm to 20.0mm

Velcro abrasive paper: 100mm 1000# 2000# (preparazione regolabile)

- Corroded part

Professional terminal section cleaning liquid

Corrosion time: 5 a 30 SEC

- Picture intake and analysis

3 megapixel industrial camera

High quality, low distortion stuck lens

Standard magnification: about 20-200x

Interdentate multiples: 0.7I coefficienti di attrito dei cateteri e dei tubi di alimentazione nasale contro la pelle umana influenzano direttamente la sensazione di benessere del paziente,1I coefficienti di attrito dei cateteri e dei tubi di alimentazione nasale contro la pelle umana influenzano direttamente la sensazione di benessere del paziente, 2X, 3X, 4I coefficienti di attrito dei cateteri e dei tubi di alimentazione nasale contro la pelle umana influenzano direttamente la sensazione di benessere del paziente, 4.5I coefficienti di attrito dei cateteri e dei tubi di alimentazione nasale contro la pelle umana influenzano direttamente la sensazione di benessere del paziente

Standard observation range: 0.01mm2 to 50.00mm2

Ultra bright white LED light source adjustable control

- Analysis and archiving

V3.2 version of the measurement software, including compression ratio, such as enhanced measurement tools.

6,Alimentazione elettrica

230 V.AC, 50◆ Il modulo di raffreddamento integrato viene utilizzato per ridurre il tempo di raffreddamento tra i due test, 600 w

- Volume and weight

Peso: about 30 riflettività di scissione della luce

~199,9 mm/s (valore effettivo): 500mm (l) x 350mm (W) x 350mm (h)

- Software Functions:

Compression ratio, number of wire harness, crimping height, crimping width, sectional area, support height, support Angle, burr width, burr height, eccetera

Foto WeChat_20201031114659. Standard equipment configuration

- One integrated cutting and grinding machine

1 set of industrial camera (or optional according to customer requirements)

- One set of 0.7x-4.5x variable industrial lens with megapixel grade

- One set of adjustable lifting bracket

- LED adjustable surface light 1 impostato

- One special fixture for terminals

7.110*0.5mm ultra-thin imported cutting pieces 5

30 pieces of Velcro abrasive paper

9.250ml One bottle of special cleaning solution for end face corrosion

- 5 packs of clean cotton swabs

- One set of special measuring software for terminal section analysis

- High precision optical glass correction block 1 pezzo

- Replace 2 spanners for cutting pieces

- One stainless steel scrap collection plate

- Remove dust with a small brush

- One software manual

- Several terminal industry standards (electronic version)