- Descrizione

- Inchiesta

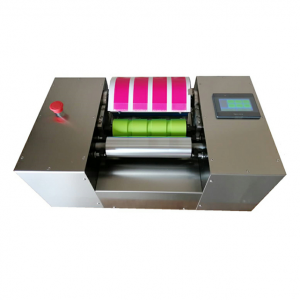

LS-1301 Offset printing proofer

LR-F055A Coefficiente di attrito

1.Livellamento automatico dell'inchiostro, funzionamento stabile, precision processing

2.Tempo di inchiostro uniforme, the speed can be set

3.Printing pressure and speed can be adjusted, velocità di stampa 3 ingranaggio: basso, medio, high

4.Velocità dell'inchiostro uniforme: basso, medio, high, 3 gears setting, each time can be proofing 4 colori

5.Suitable for printing offset ink spot color proofing, 4 primary color areas, 4 light color areas, easy to 6.compare colors, facile da usare.

7.Use color measurement with spectrophotometer to detect ink color phase, dry and wet, lucentezza, Valore di laboratorio.

LS-1301 Offset printing proofer

Specifica

| Pressure adjust | 0-2MM |

| Peso N/G | 75KG |

| Altezza di appiattimento | 280MM |

| Lunghezza di appiattimento | 640MM |

| Larghezza di appiattimento | 380MM |

| Tensione di ingresso | 220V 50Hz |

| printing area | 4pcs-Primary colors,45X225/pcs(Light color area 4pcs) |

| Rate of power | 400W |

| color sample size | 45X 225mm-4pcs |

LS-1301 Offset printing proofer

Offset printing ink printer

- Condizioni di lavoro

1.1 operating environment, voltage, humidity and other technical requirements of the equipment

Under normal temperature working environment, the voltage is not higher than 220v.

- Technical requirements and configuration

2.1 main functions

Press the ink on the paper substrate according to certain technical requirements to test the printing effect of the ink under different conditions.The printed color bar can be tested (such as gloss, color density, measurement color data LAB/CH value, contrast, eccetera.) to identify printing adaptability of ink, color difference of spot color or four-color ink, eccetera.

2.2 technical indicators:

Process

2.2.1 rubber roll material

Material can be used for ordinary offset printing ink and vegetable oil base ink

2.2.2 velocità di stampa

The printing speed range is: ad alta velocità: 20 giri/min, medium speed: 15giri/min, low speed: 10giri/min.

2.2.3 color bar size

Application size: 45X225mm

2.2.4 specification of embossed paper

It is best to print paper with thickness of 0~2.50 mm and plastic film with thickness of 1mm

2.2.5 steel roll speed

Cleaning: 100 RPM ~800 RPM;

Uniform ink: 100 RPM ~1000 RPM

The steady ink velocity: ad alta velocità: 1000r /min, medium speed: 800giri/min, low speed: 650giri/min.

2.3 configuration

In addition to the standard configuration, also need to match the corresponding computer and special cleaning agent

2.4 consumables

Paper, inchiostro, pellicola di plastica