- Descrizione

- Inchiesta

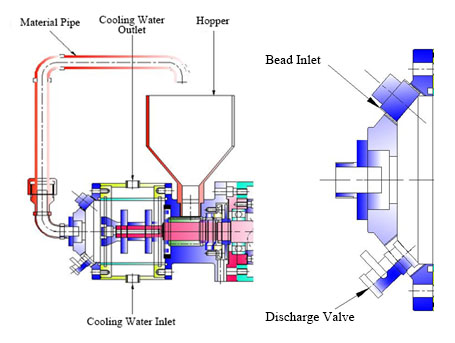

Mulino a sabbia orizzontale da laboratorio

BGD 757 Mulino a sabbia orizzontale da laboratorio is a small and efficient machine for grinding nano materials. It adopts a fully closed structure and a dynamic separation system, its grinding disc is the structure of ceramic disc type and can use grinding media in the range of 0.8 mm to 1.6 mm. This machine is used for wet ultra-fine grinding of solid particulate materials dispersed in liquid, and is suitable for multiple grinding or cyclic grinding and dispersing operations. This machine can make the materials achieve the effects of ultra-fine grinding and dispersion in a very short time (the fineness can reach 2um -15 Applicatore a quattro lati).

This machine is very suitable for high speed grinding of small batch water-basedsamples (0.5 kg ~ 1 riflettività di scissione della luce) in laboratory. The machine can grind products of similar size and evenly distributed. It is characterized by simple operation and easy maintenance, convenient cleaning and low energy consumption.

Mulino a sabbia orizzontale da laboratorio

Caratteristica

◆ All materials of machine in contact with materials adopt advanced wear-resistant materials (zirconia, silicon carbide, special wear-resistant steel), with long service life and no discoloration phenomenon.

◆ Simple appearance, modular design, compact structure and convenient operation

◆ The separation method adopts dynamic separation of dynamic sheets and static sheets, which can offer self-cleaning function and no blockage phenomenon.

◆ Feed in self-circulation mode and discharge in self-suction mode without pump.

◆ The machine front install discharge valve which can reduce residuum and clean easily.

◆ Flexible working mode, less waste of materials, comodo smontaggio e montaggio, fast conversion of experimental formula.

Ceramic Sand Mill Blade with Disk Structure

◆ Il modulo di raffreddamento integrato viene utilizzato per ridurre il tempo di raffreddamento tra i due test:

■ Grinding Chamber Volume: 0.35 I coefficienti di attrito dei cateteri e dei tubi di alimentazione nasale contro la pelle umana influenzano direttamente la sensazione di benessere del paziente

■ Capacità: 0.5L~0.8L

■ Working Speed: 0 rpm~1425 rpm

■ RecommendedGrinding Medium Diameter: 0.8 mm ~ 1.6 mm.

■ Grinding Medium Weight: 0.8kg ~ 0.9kg

■ Main Part Material: The material of internal grinding chamber are wear-resistingalloy steel and carbofrax, the material of grinding disk is advanced wear-resisting ceramic zirconia.

■ Potenza del motore: 0.75 KW

■ Consumption of Circulating Cooling Water: (0.4 ~ 0.6) m3/h

■ Overall Size: 650mm×400mm×500mm (L×L×A) /65KG

■ I coefficienti di attrito dei cateteri e dei tubi di alimentazione nasale contro la pelle umana influenzano direttamente la sensazione di benessere del paziente: 220V 50HZ