- Deskripsi

- Penyelidikan

Vacuum plasma surface trentment machine,Drum type 360-degree plasma cleaner,Miniature plasma generator

Karakteristik produk

1. Change the surface properties of materials, improve adhesion

2 The equipment adopts PLC touch screen control, simple operation and easy maintenance

3. Unique electrode structure, ensure plasma uniformity

4. Good safety, multifunctional safety protection

5. Improve production quality, environmental protection and energy saving

Vacuum plasma surface trentment machine,Drum type 360-degree plasma cleaner,Miniature plasma generator

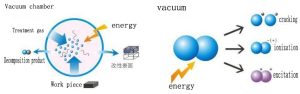

Plasma cleaning principle

plasma cleaning technology uses the characteristics of low temperature plasma to contact and react with the surface of the material, so that the surface of the material being treated can be cleaned chemically and physically, improve the surface moistness, implant new chemical functional groups and surface etching.

Vacuum plasma surface trentment machine,Drum type 360-degree plasma cleaner,Miniature plasma generator

Parameter produk

Application industry

Photoelectric and electronic industry applications

1. Semua jenis pembersihan permukaan kaca, improve the hydrophilicity of glass surface, optimize the process of glass coating printing, bonding and spraying;

2. Pembersihan kontak papan sirkuit cetak yang fleksibel dan tidak fleksibel, Lampu neon LED “contact cleaning and improve the surface glue fastness; 3. Komponen elektronik, pembersihan PCB, IC and other surface cleaning, pengikatan peningkatan aktivasi, dll. 4.LCD terminal before bonding plasma cleaning;

Aplikasi industri otomotif

1. Car EPDM seal strip, flocking and coating pretreatment instead of the use of bottom coating

2. Dasar lampu mobil, alur, Pedal Rem, ikatan bemper, pretreatment plasma sebelum disemprotkan;

4. Welding of battery pole piece for new energy automobile, activation of surface before coating, pembersihan, dll.

Aplikasi industri plastik

1.hal, PVC, PELIHARAAN, komputer, pe, PTFE dan jenis penyemprotan bahan plastik lainnya, pencetakan, pelapisan listrik, bonding and flocking pretreatment;

2. Semua jenis plastik, silikon, Gambar WeChat_20201102150327, penyemprotan logam dan bahan lainnya, pencetakan, plating bonding before surface modification, penghapusan polutan permukaan;

3. Pretreatment before printing and painting of mobile phones, komputer, toys and other plastic shells to improve surface adhesion;

4. Pra-pemrosesan botol kosmetik plastik sebelum dicetak, improve surface adhesion can prevent word falling off and improve product quality;

Aplikasi industri pengemasan

1. Professional improvement of coated paper, kertas kaca, pemolesan, kartu emas dan perak, kertas berlapis aluminium, UV, OPP, hal, PET dan kotak warna lainnya, tahan luntur kotak tempel permukaan kotak warna;

2. Plasma pretreatment before welding of milk powder cans and beverage cans;

Aplikasi industri percetakan dan pengkodean

1. Pretreatment plasma sebelum pencetakan pad, sablon dan jet coding pada permukaan plastik, logam, kaca dan material komposit lainnya untuk meningkatkan daya rekat permukaan material ke tinta;

2.pe, PTFE, silicone rubber wire and cable coding pre-processing

3.PVC, PELIHARAAN, ABS smart card coding pre-processing

Aplikasi industri peralatan

1. Plasma activation before surface coating, spraying and bonding of daily necessities and household appliances can improve surface adhesion and bonding force.

2. Pre-printing processing, which can make the printing more firm and not fall off:

GD-30 series plasma cleaner is located in the industrial production of low temperature plasma treatment equipment, widely used in electronics, solar energy, otomotif, tekstil, packaging printing, biomedical and general industries, its characteristics are high processing efficiency, pengulangan yang baik, stabilitas yang baik, pengoperasian yang mudah, variety of process parameters, diversified tasks. It is suitable for cleaning, activation, improving adhesion, adhesion and etching and other processes, and can be customized according to different needs of customers with professional, efficient and stable solutions, which perfectly fit the medium and large production needs of enterprises and companies.

GD-30 series plasma cleaner is located in the industrial production of low temperature plasma treatment equipment, widely used in electronics, solar energy, otomotif, tekstil, packaging printing, biomedical and general industries, its characteristics are high processing efficiency, pengulangan yang baik, stabilitas yang baik, pengoperasian yang mudah, variety of process parameters, diversified tasks. It is suitable for cleaning, activation, improving adhesion, adhesion and etching and other processes, and can be customized according to different needs of customers with professional, efficient and stable solutions, which perfectly fit the medium and large production needs of enterprises and companies.